Weigh stations serve a critical function in the commercial trucking industry, compelling drivers to stop for essential inspections that ensure safety, regulatory compliance, and protection of public infrastructure. For logistics and freight company owners, understanding the significance of these stops is crucial. This article delves into the reasons why commercial trucks must stop at weigh stations, with insights tailored for procurement teams in construction and mining, as well as small business owners managing delivery fleets. Each chapter will offer a detailed examination of a specific aspect—enforcing weight limits, ensuring road safety, verifying compliance, maintaining fair competition, and protecting public infrastructure—demonstrating how these components work synergistically to enhance the efficacy and safety of the trucking industry.

Balancing the Road: How Weigh Stations Enforce Weight, Safety, and Fair Play

A line of semi trucks climbs toward the weigh station like a slow-moving procession, each vehicle carrying a responsibility that reaches far beyond its own cargo. Weigh stations are not merely checkpoints; they are the practical embodiment of a system that must balance efficiency with accountability. When a truck rolls onto a scale, the act is almost ceremonial in its simplicity: the vehicle is weighed, inspected, and, if necessary, redirected to address a problem before it becomes a problem on the highway. Yet that simple weighing is underwritten by a complex calculus about what keeps roads from breaking, how drivers stay safe, and why all operators deserve a level playing field. Enforcing weight limits is not just a rule to be followed; it is a mechanism that preserves the road’s endurance while safeguarding every traveler who shares the pavement.

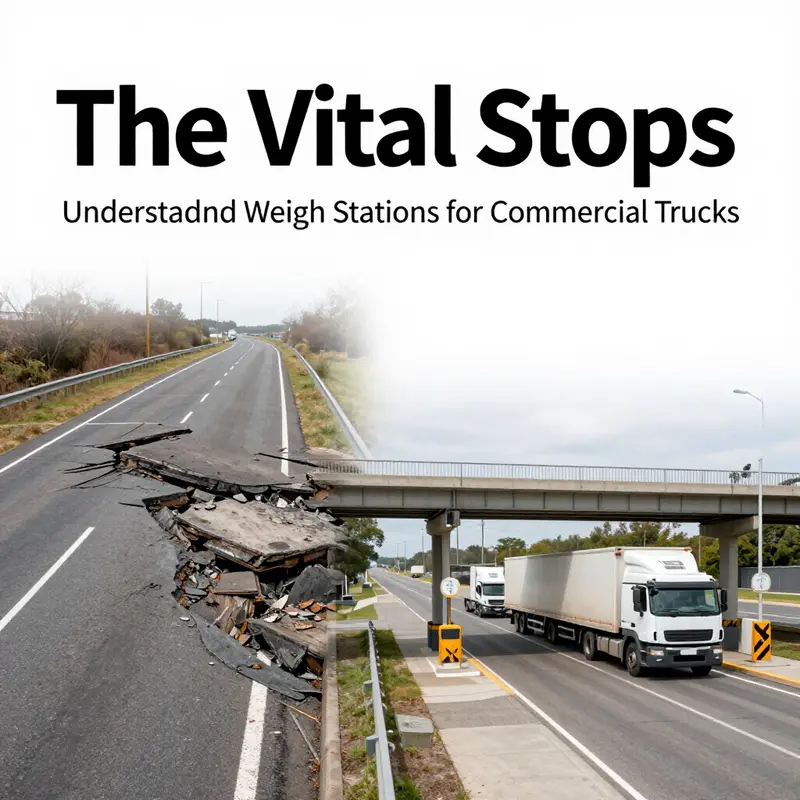

Fundamentally, weight limits exist because every mile of highway carries its own toll—on asphalt, substructure, bridges, and the surrounding taxpayer-funded network designed to keep commerce moving. The limits are laid out through federal and state regulations, with values that are the result of engineering studies. They reflect a practical compromise between the weight a road can bear and the weight a truck can carry efficiently. Trucks that exceed these limits do more than strain a road surface; they accelerate the fatigue of pavements and bridges, increasing the likelihood of early cracks, rutting, and, in worst cases, structural damage that requires costly repairs and traffic disruption. When authorities check weights at a station, they are translating that engineering judgment into a concrete obligation for every operator: stay within the limit, and you contribute to a safer, longer-lasting highway system. If the scale shows an overweight vehicle, penalties follow. Fines can be issued, cargo may need to be offloaded to bring the vehicle into compliance, and in some cases the operator may be temporarily denied access to certain routes. The consequences reinforce a critical point: the system is designed not to punish but to prevent harm and to uphold a standard that protects the road as a shared public good.

The enforcement mechanism itself is a blend of old and new technology, where tradition meets innovation. Physical scales, calibrated and maintained, provide the hard data that determines compliance. In many jurisdictions, regulators pair these scales with a broader inspection process. This means that while a truck is being weighed, inspectors also assess operational safety features—brakes, tires, lights, and the way cargo is secured. The aim is not to penalize in isolation but to ensure that a vehicle is safe to operate in addition to being the right weight. This comprehensive approach helps prevent incidents that would otherwise arise from combining improper weight with degraded brake performance or insecure loads. It is a reminder that weight enforcement sits at the crossroads of safety and infrastructure stewardship.

Modern weigh stations are increasingly sophisticated. Weigh-in-Motion (WIM) technology allows certain vehicles to be screened at low speeds without coming to a full stop, provided they fall under the threshold weight. This improves traffic flow and reduces congestion while preserving the integrity of enforcement. Yet the central purpose remains the same: to identify vehicles that pose a risk to road safety or infrastructure and to address the risk before it materializes into a failure on the highway. The data generated by these systems is more than a temporary pass/fail record; it becomes a diagnostic thread for transportation agencies. When engineers plan maintenance, they rely on patterns of wear that are, in part, driven by heavy vehicles. WIM data helps determine where to prioritize repaving, overlay work, or bridge rehabilitation. In this way, weigh stations contribute to a longer-term strategy for the road network, translating individual truck incidents into broad planning decisions that stretch across years and seasons.

The social and economic rationale for enforcing weight limits extends beyond the pavements themselves. Different operators compete on price and efficiency, which can tempt some to push weight limits to the edge in pursuit of greater payload and profit. Weigh stations help level the playing field. If one fleet consistently overfuels its payload, it can gain a short-term advantage at the expense of everyone else and, crucially, at the expense of safety and road longevity. Enforcement thus protects honest operators who invest in compliant practices and in vehicles that are genuinely safe to operate. It creates a predictable regulatory environment where compliance is expected and noncompliance carries real consequences. In that sense, weigh stations serve as a referee in a highly competitive industry, ensuring that competition does not erode safety or infrastructure standards.

The relationship between weight enforcement and public finance is often overlooked. Roads and bridges funded by taxpayers deserve protection from accelerated wear caused by overweight trucks. When heavy freight overwhelms a roadway, the cost of repairs is borne not by the guilty carrier alone but by the public purse. The weigh station, therefore, acts as a guardian of public resources, aligning private incentives with the broader interest of a durable transportation network. This alignment is particularly important in countries with centralized regulatory frameworks, where agencies use a combination of on-site inspection and data-driven planning to manage the highway system. For professionals in the field, the payoff of strict weight enforcement is measured in fewer potholes, longer bridge lifespans, and a transportation network that remains capable of handling growing freight demands without escalating tax burdens.

The chapter’s throughline is clear: weight limits are a practical instrument for safety, reliability, and fairness. They are not arbitrary numbers but the outcome of engineering analyses that seek to prevent harm to the road and to the people who use it. Weigh stations crystallize that analysis into action, stopping or slowing down overweight trucks and prompting corrective steps that can prevent larger problems down the line. The weight check is a first line of defense, but it is complemented by an inspection that probes deeper into a vehicle’s condition. A truck that is compliant in weight but deficient in brakes or lighting is still a hazard on the road. The converse is also true: a well-maintained vehicle that carries an excessive payload can still cause damage or pose a risk in certain circumstances. The dual checkpoints—weight and safety inspection—work together to ensure that the truck, the cargo, and the road share a common duty to safety and efficiency.

As a marker of industry trends, the interplay between weight enforcement and market dynamics offers a telling view of how regulation adapts to change. Capacity fluctuations and the demand for reliable, compliant transport services can influence how fleets approach weight and routing. For readers seeking a broader perspective on how capacity and regulation shape the trucking landscape, this chapter can be read alongside analyses that examine excess capacity in the trucking market insights, which explore how fleet counts, demand cycles, and regulatory stability interact to influence pricing and lanes. excess-capacity-in-the-trucking-market-insights

The official heart of weight enforcement remains anchored in the long-standing collaboration between federal guidelines and state implementation. The Federal Highway Administration maintains a detailed resource outlining the purpose, methods, and rationale for weight enforcement. This external reference provides a formal backdrop to the everyday experience at a weigh station, showing how the policy tools unfold in practice and why the enforcement regime persists as a core element of highway safety and infrastructure protection: https://www.fhwa.dot.gov/infrastructure/weight_enforcement.cfm. The combination of real-world enforcement and authoritative guidance helps illuminate why weigh stations matter so much more than the brief pause at the scale. They are, in essence, a structured response to the challenge of keeping freight moving safely over a shared, finite, and aging road network.

Measured for Safety: Why Weigh Stations Are Crucial for Safe, Fair, and Durable Road Freight

Weigh stations are more than roadside checkpoints. They are a foundational element of a system that aims to keep highways predictable, bridges intact, and the people who drive and ride on these roads safer. At the core, the purpose is straightforward: ensure that commercial trucks do not exceed legal weight limits. But the ripple effects of that check reach far beyond a single axle or a single highway. When a truck rolls slowly onto a scale, the moment seems simple enough—gravity, measurement, a verdict. Yet what unfolds next is a cascade of safety and public-interest concerns. Overloaded vehicles threaten everyone sharing the road. Excess weight increases braking distance, changes a truck’s braking dynamics, and heightens the chance of tire failure or wheel end problems. A hard stop on a slippery or uneven surface can become a matter of life and death, and the danger compounds when a heavy load is carried on tires that are already stressed or mismatched for the journey ahead. By catching overweight trucks before they join the flow of traffic, weigh stations reduce the probability that such incidents will occur and that users of the road will bear the consequences in the form of accidents, injuries, or worse.

Weigh stations also serve the broader mission of infrastructure protection. Roads and bridges are designed to bear specific loads, and those designs assume a distribution of weight that aligns with engineering standards. When trucks are overloaded, the stress on pavements, joints, and bridge components becomes concentrated in ways the original design did not anticipate. The result can be faster wear, more frequent repairs, and, eventually, more costly disruption for all road users. The public cost of neglected compliance is not theoretical; it translates into tax dollars spent to repair damage that proper weight enforcement could have prevented. In this sense, weigh stations are a fiscal safeguard as much as a safety measure.

The enforcement dimension is equally important. Weigh stations sit at the intersection of safety rules and real-world accountability. The process typically involves a driver approaching the station and guiding the vehicle over in-ground scales that relay weight data in real time. Officers or automated systems evaluate whether the gross vehicle weight and individual axle loads comply with federal and state limits. The result can range from a clearance to proceed to an enforcement action if a truck is found to be overweight. Beyond weight, inspectors often conduct a broader safety review, checking brakes for proper function, tires for wear and pressure, lights for visibility, and cargo securement for secure transport. This broader inspection posture reinforces the principle that a truck is a system, not a single component, and a failure in one part can compromise the whole vehicle’s safety.

The science behind these rules is not arbitrary. Heavier loads do not distribute evenly across a road or a bridge. The weight a truck carries is not a single point of strain; it is shared across axles and tires, with the distribution dependent on the configuration of the vehicle and the spacing between axles. Engineering frameworks, such as formulas developed to protect bridges and highway surfaces, guide what is permissible. The most well-known approach employs axle counts and the distances between them to determine the safe carrying capacity. This method helps prevent situations where a truck might be technically within a gross weight limit but still impose harmful stress patterns on a critical structural element. Without such calculations, a sequence of overburdened trips could gradually erode the long-term integrity of roads and over time lead to expensive, widespread repairs.

From a safety perspective, the link between overweight heavy trucking and accident risk is clear. A vehicle that carries more weight faces longer stopping distances, greater kinetic energy to manage in curves, and a higher likelihood of tire blowouts or brake overheating. Even a small percentage of overloading can tilt the safety balance toward increased risk, especially in adverse weather, on grades, or in the presence of imperfect driver response. Weight enforcement thus acts as a tangible brake on a chain reaction: reduce the number of overweight trucks on the road, and you lower the potential for incidents that can cascade into traffic disruption and harm.

Weigh stations are also a crucial component of a broader regulatory framework designed to maintain a level playing field for operators. When a truck is found to exceed weight limits, penalties can be severe—fines, vehicle immobilization, or other sanctions. These consequences, coupled with the knowledge that enforcement can and does occur, deter weight violations and encourage compliance across the industry. In this way, weigh stations support fair competition by ensuring that all operators meet the same safety standards and infrastructure-use expectations. The public benefits are as much about public safety and fairness as they are about safeguarding taxpayers’ investment in transportation networks.

Technology has expanded the reach of weigh station systems while preserving their essential functions. Weigh-in-Motion (WIM) technology allows for continuous monitoring on major corridors, reducing the need for every truck to stop for a full static weigh. Yet WIM is not a replacement for traditional scales; rather, it complements them by enabling more efficient screening and by directing trucks to full inspections when necessary. The physical weigh stations remain vital for definitive measurement, regulatory enforcement, and comprehensive safety checks, reinforcing the idea that weight is one dimension of a complete safety assessment rather than a standalone gatekeeper.

Cross-border and multi-jurisdictional considerations add another layer to the purpose of weigh stations. In regions with extensive highway networks and busy cross-border traffic, weigh stations help harmonize weight enforcement across different authorities. They act as a practical convergence point where different regulatory regimes meet, ensuring that heavy vehicles cannot bypass local standards by crossing a border or switching jurisdictions. Policy discussions that address how to balance enforcement with traffic flow and economic efficiency often explore these kinds of cross-cutting measures. For readers who want to see how these policy conversations translate into practice, a discussion on bridging border barriers and meeting insights offers useful context and depth. Bridging Border Barriers Meeting Insights

In the end, weigh stations are not simply about catching violators; they are about protecting a complex system that carries people, goods, and energy across vast distances. They help ensure that roads stay safer, bridges stay stronger, and the myriad stakeholders—from passenger vehicle drivers to long-haul operators and the communities that rely on efficient freight movement—benefit from a predictable, well-regulated transport network. They support a framework in which safety considerations are inseparable from the economic realities of moving goods, and they remind us that the public infrastructure that underpins modern commerce is not free or infinite. A truck that complies with weight and safety standards preserves this infrastructure for the long term, preserving reliability and reducing the need for disruptive repairs that would ripple through supply chains and everyday life.

For readers seeking a broader, official perspective on the science and policy behind weight regulations, the U.S. Department of Transportation provides detailed resources that ground these discussions in widely accepted engineering practice and regulatory structure. External references can illuminate the rationale behind the practice and help contextualize weigh station operations within the national transportation framework. External reference: https://www.transportation.gov/

Highway Gatekeepers: How Weigh Stations Turn Regulations into Safer Roads and Fair Competition

Along the spine of every major highway system, weigh stations sit like quiet sentinels. They are more than checkpoints; they are nodes in a complex, technology-enabled framework built to protect people, preserve road life, and keep the economics of trucking honest. For drivers and fleet managers, the stop is a routine disturbance in a tightly choreographed day. For regulators, it is a live, practical test of physics, safety, and compliance. The result is a robust mechanism that translates heavy trucks into measurable risk factors, and weight into safety outcomes. When a tractor-trailer rolls onto a scale, it is not merely about meeting a number; it is about whether that number reflects the vehicle’s impact on pavement, bridges, and the ability of a driver to stop safely under real-world conditions. In that sense, weigh stations are both guardrails and data points, guiding behavior while yielding insight into how our infrastructure handles commerce at scale.

At the core of these checks is the weight limit, a constraint anchored in engineering realities rather than arbitrary preference. The Federal Bridge Formula, a cornerstone of federal and state weight regulation, calculates the maximum permissible load based on axle count and the spacing between axles. This isn’t a nominal rule; it is a calculated boundary designed to distribute force across multiple supports and to keep concentrated loads from producing disproportionate stress on pavements and bridge structures. Each axle and gap in a truck configuration carries a specific share of the total load, and the formula translates those shares into a total weight that can safely travel a given route. When a rig arrives at a weigh station, the scale captures the gross vehicle weight and, crucially, the inspectors compare that measurement against the permissible envelope for that vehicle’s wheel arrangement. If the numbers fit within the envelope, the truck proceeds; if not, the vehicle is subject to corrective steps, penalties, or more in-depth inspection.

For truckers, those checks are a direct line to the bottom line. Overweight vehicles invite fines that can escalate quickly, and in many jurisdictions, exceedances can trigger vehicle impoundment or mandatory corrective action. Beyond the immediate cost, there is the risk of substantial delays that ripple through delivery windows, contract commitments, and customer satisfaction. Regular compliance reduces these ups and downs, fostering trust with regulators and with customers who rely on predictable service levels. In a highly competitive industry, steady adherence to weight limits helps protect a carrier’s reputation for responsibility and safety, which can translate into better access to lanes, favorable contracts, or simply smoother operations against a backdrop of rising capacity constraints and fluctuating demand.

But weight is only one part of the picture. Weigh stations are increasingly part of broader inspections that assess a vehicle’s overall safety readiness. Inspectors may review brake performance, tire condition, lighting, and the securement of cargo. Poor braking or worn tires can turn a supposedly compliant load into a rolling hazard, while loose or shifting cargo increases the risk of loss, rollover, or destabilizing momentum during braking. In this way, weigh stations function as a comprehensive safety net, catching issues that a driver might not notice in the moment or that a pre-trip checklist could miss. The joint focus on weight and safety aligns with a larger principle: the road is a shared resource, and each operator must demonstrate that their vehicle can use it without imposing unacceptable risk on other users.

The rationale behind these checks extends beyond immediate safety concerns. A consistent, level playing field is essential for fair competition in a market characterized by high fixed costs, tight margins, and volatile demand. When some operators seek to reduce costs by loading beyond legal limits, the safety case weakens not just for the offending carrier, but for the entire ecosystem of logistics and distribution. Weigh stations, by enforcing uniform rules, curb this opportunistic behavior and help prevent a deterioration of standards that could otherwise erode public confidence in road safety. In this sense, compliance is more than a legal obligation; it is a social contract that protects taxpayers who fund road maintenance and whose communities rely on reliable freight connections for everyday goods and services.

Technology has reshaped how weigh stations operate, making compliance more efficient and more accessible to drivers who seek to stay within legal bounds. Traditional static scales still serve as definitive measuring points, but modern systems increasingly incorporate automated, remote, and weigh-in-motion (WIM) capabilities. These tools can pre-screen vehicles or allow for rapid rechecks without forcing trucks to stop for extended periods. For drivers, this means shorter waits and clearer feedback about whether adjustments are needed before they reach a full stop on the scale. For regulators, technology enhances accuracy, reduces human error, and adds data streams that can illuminate trends in weigh violations, vehicle performance, and load-shift frequencies. The result is a more predictable and safer network, where the chance of a violation slipping through the cracks is diminished and the cost of non-compliance is made steadily apparent.

The evolving regulatory landscape also intersects with broader policy conversations about cross-border trade and regional harmonization of standards. For fleets operating beyond a single jurisdiction, understanding how weight rules translate across borders becomes a practical concern, influencing routing decisions and fleet composition. This is reflected in ongoing discussions and regulatory exchanges that shape how inspections are conducted at the frontier, where the same vehicle might encounter different thresholds and procedures. For readers who want to explore these dynamics further, a focused look at cross-border regulatory issues provides a window into how shifts in policy can cascade through compliance practices and route planning. See the TCAs cross-border regulatory issues event for a deeper dive into these conversations.

Ultimately, weigh stations embody a shared commitment to safety, infrastructure preservation, and level competition. They translate the abstract logic of engineering formulas into everyday consequences for drivers, fleets, and communities. They remind us that the highway is a finite and valuable public asset, and that maintaining it requires vigilance, consistent rules, and the willingness to invest in the systems that enforce those rules. The immediate effect is seen in safer highways and more reliable deliveries; the broader effect is a transportation sector that can plan, invest, and grow with a clearer sense of the boundaries within which it must operate. As the system continues to adopt smarter detection, better data analytics, and more seamless queuing processes, the basic purpose remains the same: to ensure that the weight of progress does not come at the cost of safety, and that every truck is measured not just by mass but by its readiness to share the road responsibly. For readers looking to connect these regulatory concerns with practical operations, the coming chapters will examine how fleets translate compliance into strategy, maintenance planning, and capital investments that keep wheels turning without compromising safety or fairness. External resources provide a broader view of the regulatory foundations behind these checks, including the Federal Bridge Formula and related standards accessible through the U.S. Department of Transportation. See the official site for more context on the engineering principles that power weigh-station enforcement: https://www.transportation.gov.

Additionally, regulatory theory and cross-border considerations are actively shaping how inspections are performed and how fleets adapt. For ongoing discussions on cross-border regulatory issues that influence weigh-station practices, you can explore TCAs cross-border regulatory issues event. TCAs cross-border regulatory issues event

Balancing the Scales on the Highway: Weigh Stations as Gatekeepers of Safety, Standards, and Fair Competition

On the surface, weigh stations might resemble simple checkpoints—points along a long highway map where trucks pause and paperwork is checked. Yet they anchor a much larger system built around safety, accountability, and a level playing field. When a fleet rolls into a weigh station, it is not merely proving a weight; it is a test of whether that weight has been loaded and distributed to respect both the vehicle’s design and the road it travels. The logic is straightforward, but its consequences ripple through the economy: if every truck carried only what the legal limits permit, wear and tear on pavement would lessen, repair costs would stabilize, and the risk to motorists would decline. The challenge, of course, is enforcement. The road cannot be policed perfectly at every mile, but weigh stations provide a strategic choke point where compliance can be verified and noncompliance deterred. In this sense, weigh stations do more than police loads; they preserve the integrity of the entire trucking ecosystem, from safety inspectors in state fleets to shippers, brokers, and drivers who depend on predictable metrics for planning and performance.

Weight limits are a standard. They reflect not only legal requirements but the practical physics of moving heavy masses. An overloaded truck demands more fuel, is harder to stop, and strains brakes and tires beyond what safety margins allow. It also causes more road damage, especially on bridges designed for specific loads. When inspections confirm weight within limits, they reinforce that capacity has real costs: older equipment requires maintenance, more frequent brake testing is needed, and tires wear unevenly. Weigh stations help ensure that those costs are shared by the right players, not borne by taxpayers or passed on as lower margins for those who cut corners. This symmetry matters for competition. If a carrier can shave costs by simply adding more weight, they can offer lower prices or faster service, creating an unfair incentive that invites others to abandon safe practices. The result is a rot that can erode reliability and safety across the entire network. Weigh stations counter that rot by creating a common standard that is difficult to bypass without consequences.

Enforcement rests on more than a scale. At many weigh stations, inspectors examine brakes, lighting, tires, and cargo securement as part of a broader safety audit. Trucks found to be overweight may face fines, impoundment, or orders to correct issues before continuing. The penalty structure, combined with the visibility of a checkpoint, acts as a deterrent against disassembly of loads or the strategic shifting of weight to regions where enforcement is weaker. The deterrent effect matters because it reduces the temptation to cheat, not only for dramatic overweight cases but for subtler, recurring patterns of poor maintenance. In practice, a fair system keeps a company from using under-maintained equipment as an edge over compliant operators. It is difficult for a single fleet to prosper while others degrade safety in pursuit of profit. The weigh station’s role is to ensure that the entire market functions with predictable rules. The effect is not merely punitive; it is educational. Operators learn to budget for maintenance, plan routes with safe margins, and invest in equipment that performs reliably under legal constraints. The long-term gain is stability: drivers who trust the rules, shippers who can forecast risk, and the public who relies on safe highways.

Beyond safety and fairness, weigh stations protect public infrastructure and the investment taxpayers make in roads and bridges. Heavy trucks leave deeper scars on pavement and accelerate wear on critical structures. When overloads go unchecked, the cost of repairs rises, and the burden falls on future transportation budgets and tolls that must be raised or projects delayed. By maintaining weight limits in practice, weigh stations help manage that financial equation. They ensure that the most expensive elements of the network—the bridges and long-haul corridors—receive the discipline they require. In this sense, the stations function as a public good, aligning private incentives with societal needs. They also influence urban and regional logistics strategies. Carriers who operate within standards can plan more predictable maintenance cycles, while those who have tested the limits may encounter more frequent inspections and corresponding downtime. The net effect is a more reliable network where capital decisions, not patchwork fixes, determine capacity and service levels.

Technological progress has gradually reshaped how weigh stations operate. Weigh-in-Motion systems allow trucks to be weighed as they roll over sensors, or to be weighed with minimal stops, reducing traffic disruption and improving flow in high-volume corridors. Portable or distributed in-motion scales give inspectors flexibility when a full station is impractical, enabling real-time checks in rural or pinch-point locations. These tools broaden the effectiveness of enforcement without creating new bottlenecks. They also promote a culture of continuous compliance, since operators cannot easily game a system that momentarily hides overweight loads. As enforcement becomes more precise and less disruptive, the social contract between industry and regulator strengthens. Carriers that invest in safe compliance gain reputational benefits and smoother operations, while those tempted to push the limits face clearer consequences. In this evolving ecosystem, weigh stations remain a human-centered checkpoint where people, procedure, and technology converge to keep speeds safe and weights within the law.

Within this framework, weigh stations influence market dynamics by upholding fair competition. When every operator faces the same probability of inspection and the same penalties for violations, price competition tilts toward service quality, reliability, and efficiency rather than risky shortcuts. This is more than abstract economics; it is the practical reason fleets invest in safer brakes, more durable tires, and better load management systems. It also means brokers and shippers can rely on consistent performance from the carriers they partner with, knowing that safety and legality are not negotiable terms. The balance is delicate. A market can enjoy healthy competition only when safety standards remain credible and enforceable. Operators who would otherwise drop maintenance costs at the expense of road safety find that weigh stations enforce a credible baseline, discouraging the most harmful forms of cutting corners. In this sense, weigh stations contribute to a self-regulating system: when the playing field is level, the best-equipped, best-trained fleets tend to win through efficiency and service rather than by bending the rules.

Readers looking to understand how broader market pressures intersect with regulatory oversight may find relevant perspectives in recent insights on excess capacity in the trucking market. These discussions highlight how capacity shifts influence pricing, investment, and fleet choices while underscoring why fair enforcement matters for all players. Excess capacity in the trucking market insights. As the fleet landscape evolves, weigh stations stand as constants that preserve safety, fairness, and infrastructure sustainability, even as trucks and markets adapt to new demands and opportunities. The ongoing alignment of private incentives with public safety depends on more than a scale; it depends on a shared recognition that rules are designed to protect everyone who uses the road. For this reason, weigh stations are not isolated enforcement points but integral elements of a transportation system that strives to be predictable, resilient, and just. External resource: https://www.fmcsa.dot.gov

Guardians at the Gate: How Weigh Stations Protect Roads, Budgets, and a Fair Freight Market

Weigh stations are often perceived as rigid checkpoints along the highway, but their role runs far deeper into the fabric of public safety, infrastructure stewardship, and the economics of freight. They stand at a crossroads of policy and pavement, where a single truck can influence the life cycle of an entire roadway network. The question of why commercial trucks must stop at these stations extends beyond bureaucratic routine; it touches the health of our roads, the safety of those who travel them, and the price communities pay for maintaining a vast and aging transportation system. In this light, weigh stations function as much as guardians of public value as they do enforcers of rulebooks, shaping behavior in ways that reverberate through budgets, logistics planning, and even the broader competitiveness of the freight sector.

At the heart of the weigh station mandate lies the simple idea of weight limits. Roads and bridges are engineered for certain loads, with axle configurations that distribute weight in ways that minimize stress on pavement and structure. When trucks exceed those limits, the concentrated pressure on road surfaces accelerates wear. The wear is not just cosmetic; it is structural. Repeated overloads bend asphalt, fracture concrete, and fatigue bridges, triggering repairs that can cascade into traffic disruptions, detours, and longer travel times for everyone who shares the road. The economic logic follows a straightforward line: heavier trucks mean faster deterioration, higher maintenance costs, and a larger slice of public funds diverted to rebuild rather than to new projects, safety programs, or street improvements that benefit all road users. By weighing vehicles, authorities create a tangible incentive for operators to respect permitted loads, closely aligning private incentives with the social costs of overloading.

Beyond the static accounting of weights, modern enforcement blends science with efficiency. Dynamic weighing, including weigh-in-motion systems, allows vehicles to be assessed while still moving or with minimal interruption to traffic flow. This shift matters because it reduces the downtime that plagues transport operations during inspections. It preserves the reliability that shippers rely on and the predictability that carriers need when they plan routes, schedules, and maintenance cycles. The result is a smoother balance between inspection rigor and roadway throughput. Yet even when trucks must physically stop at a station, the goal is not to penalize every load but to deter the practice of overloading. The presence of enforcement sends a clear message: inflating payloads at the expense of infrastructure is a lose-lose proposition, not only for taxpayers but for fleets that care about long-term cost control and equipment longevity.

Safety is another pillar of weigh station logic. Heavier trucks do not merely wear roads faster; they also alter a vehicle’s dynamics. Excess weight can compromise braking distance, steering response, and stability, particularly on curves or in poor weather. The chance of rollovers or jackknifing increases as load grows, raising the risk for drivers and others on the road. Weigh stations help remove high-risk vehicles from circulation before they become a threat to nearby cars, pedestrians, or roadside workers. In doing so, they protect the vulnerable moments of driving that statistics show are most likely to turn into serious incidents—situations that ripple through communities in the form of injuries, traffic congestion, and the all-too-human costs of accidents.

The regulatory dimension of weigh stations extends into broader fields of compliance. Weigh checks are rarely isolated; they are part of a comprehensive inspection regime. Inspectors scrutinize brakes, tire condition, lighting, and cargo securement, all of which contribute to an overall assessment of a truck’s roadworthiness. A vehicle that fails on one dimension—say, defective brakes or insecure cargo—may be held until the defect is corrected, or the operator may face penalties. This integrated approach ensures that the freight fleet operates under uniform standards, and it helps maintain a level playing field. Without such checks, operators who skimp on maintenance could undercut those who invest in safety and proper loading practices, skewing competition against responsible carriers and potentially eroding public trust in freight reliability.

The economic argument for weigh stations is as much about fairness as it is about safety and infrastructure preservation. When all operators are required to meet the same weight and safety standards, the field of competition shifts away from sheer payload volume toward reliability, safety, and efficiency. For customers and communities, this translates into more predictable delivery windows, fewer roadwork-induced delays, and a transportation system that can better absorb shocks from surges in demand or supply chain disruptions. The public sector bears the cost of maintaining roads, but with effective enforcement, those costs are spread more evenly across a system that benefits every user, from daily commuters to long-haul shippers. The result is a transportation network that is not only safer but also more resilient and fiscally sustainable over time.

From a policy perspective, weigh stations exemplify the alignment of governmental objectives with private sector incentives. The economic literature surrounding enforcement shows that deterrence is most effective when it is visible, credible, and proportionate. A 2023 federal analysis highlights how enforcement investments yield substantial returns: every dollar spent on weight-enforcement and compliance is associated with about four dollars in avoided road repair costs over a decade. That figure captures not only direct savings in pavement and bridge maintenance but also the avoided costs of traffic disruption, user delays, and emergency repairs that would arise from preventable damage. In practice, this means the presence of weigh stations contributes to lower total cost of ownership for the infrastructure system and more stable, reliable operating costs for fleets that depend on those roads.

For operators, weigh stations can be seen as both a constraint and a catalyst. The initial friction of stopping or passing through a station may be viewed as a cost, but the longer horizon rewards come in the form of safer loads, less uneventful wear on tires, brakes, and suspension, and enhanced fleet longevity. The adoption of automated weighing technologies reduces the friction further, turning compliance into a routine element of freight planning rather than a disruptive interruption. In a market where capacity, timing, and reliability increasingly determine competitive advantage, the predictability offered by stringent yet efficient enforcement creates a smoother operating environment. When carriers know that overloading will be detected and penalties levied, and when they can trust that others are playing by the same rules, the incentive to cut corners weakens. And as the industry contends with shifts in demand, driver shortages, and evolving compliance landscapes, this consistency matters more than ever.

As the freight ecosystem evolves, weigh stations remain a practical, evidence-based instrument for safeguarding public assets while supporting a fair and efficient market. They anchor a complex network of decisions made by shippers who plan routes, brokers who optimize loads, and carriers who invest in safer equipment and better load distribution. The payoffs extend beyond the immediate stop: safer roads, longer-lasting infrastructure, more stable operating costs, and a freight system that is robust enough to weather the cycles of economic change. In this sense, weigh stations are less about policing trucks and more about maintaining a shared commitment to responsible mobility. For readers who want to explore how broader market dynamics intersect with enforcement regimes, consider the broader discussion on excess capacity in the trucking market insights, which frames the ongoing balance between demand, supply, and the discipline that enforcement mechanisms help sustain. excess capacity in the trucking market insights.

The story of weigh stations, therefore, is not merely one of compliance. It is a narrative about the pragmatics of keeping a vast highway system functional and affordable. It is about ensuring that costs associated with moving goods do not fall disproportionately on taxpayers, and that the freight industry operates under clear, predictable rules that reward safety, efficiency, and investment in better load practices. The long view is not a simple tally of fines collected or trucks weighed; it is a measure of how well a society can sustain its mobility, keep essential goods moving with confidence, and maintain a transportation backbone capable of supporting future growth without bankrupting state and local budgets. For those seeking the most authoritative articulation of these outcomes, the Federal Highway Administration’s FY 2023 report on weigh station enforcement and road preservation provides a rigorous foundation for understanding the economic calculus at play and the real-world impacts of enforcement on road longevity and public finances. https://www.fhwa.dot.gov/policy/2023/fy23_07.cfm

Final thoughts

Understanding the importance of weigh stations is essential for logistics and freight companies, construction and mining enterprises, and small businesses operating delivery fleets. The enforcement of weight limits, the assurance of road safety, compliance verification, maintaining fair competition, and the protection of public infrastructure all underline the critical role weigh stations play in the trucking industry. By adhering to these regulations and practices, businesses can enhance safety, promote fairness, and contribute to the longevity of road networks, ultimately leading to more efficient and responsible operations. Embracing these requirements benefits not only the trucking companies but also the wider community that relies on safe and well-maintained infrastructure.