In an ever-evolving trucking industry, Stoughton Trailers stands at the forefront of innovation with its latest advancements in intermodal container and smart chassis design. With a remarkable 53-foot container boasting an impressive 262 cubic feet of volume, which is 6.5% more than traditional models, Stoughton is reshaping transportation efficiency. This cutting-edge design not only enhances cargo capacity but also signifies the company’s strategic return to the intermodal segment, where innovation meets practicality. By embracing such advancements, Stoughton Trailers is redefining the standards of intermodal logistics, promising significant advantages for modern supply chain operations.

Importance of Innovations in Intermodal Transportation

Innovations in intermodal transportation significantly enhance efficiency and profitability for trucking companies. Key developments include:

-

Artificial Intelligence and Machine Learning: Companies integrate AI to optimize route planning, predict maintenance needs, and improve decision-making. For instance, 3SC Solutions launched iTMS, an AI-driven transport management solution.

- Features: Real-time route optimization, predictive analytics to anticipate disruptions.

-

Autonomous Vehicles: Deployment of self-driving trucks is advancing.

- Example: Companies like Aurora Innovation and Kodiak Robotics planning routes between Dallas and Houston.

- Benefits: Counter labor shortages, improve fuel efficiency, adhere to regulations.

-

Blockchain Technology: Adoption of blockchain enhances transparency and traceability.

- Advantages: Automates processes, reduces paperwork, prevents fraud, improves inventory management.

-

Internet of Things and Telematics: Equipping vehicles with IoT sensors for real-time monitoring.

- Benefits: Predictive maintenance, optimized routes, improved safety.

-

Sustainability Initiatives: Transition to electric trucks driven by environmental concerns.

- Outcome: Year-long cost savings from reduced emissions.

Collectively, these innovations contribute to enhanced operational efficiency, reduce costs, and improve profitability for trucking companies engaged in intermodal transportation.

Evidence of Stoughton Trailers’ Design Innovations

Stoughton Trailers has made significant strides in intermodal container design with their new 53-foot domestic container, distinguished by its robust specifications and innovative features. This design marks a notable return to the intermodal segment, emphasizing enhanced freight capacity and durability.

Specifications:

- Length: 53 feet

- Internal Width: 100.375 inches (2.375 inches wider than traditional containers)

- Volume Capacity: 262 cubic feet (6.5% more than standard models)

- Materials: Composite plate-style design with weather-resistant bonded sidewall panels, utilizing domestically sourced steel and aluminum, manufactured in Wisconsin.

Capacity Benefits:

The broader internal dimensions of Stoughton’s container provide the ability to carry more cargo per load, significantly boosting operational efficiency. With an additional 262 cubic feet of volume, logistics companies can optimize space utilization, minimizing trips and maximizing payload.

Durability and Performance:

Stoughton’s innovative use of composite materials and reinforced structural components helps resist damage, leading to decreased repair costs and an extended lifecycle. Moreover, the weather-resistant sidewall panels reduce the risk of corrosion, ensuring longevity and lower maintenance.

Comparison to Traditional Models:

When stacked against conventional corrugated steel containers, which typically have an internal width of about 98 inches, Stoughton’s model offers a significant competitive edge. The additional width and volume enhance loading capabilities.

Furthermore, traditional containers often struggle with corrosion and structural fatigue; Stoughton’s strategic use of hot-dip galvanized steel for structural components not only addresses these issues but also exceeds standards set by the Association of American Railroads (AAR), ensuring compliance and reliability for intermodal transport.

In conclusion, Stoughton Trailers’ 53-foot intermodal container represents a substantial improvement over traditional models, boasting increased capacity, enhanced durability, and advanced construction methodologies that set a new benchmark in the industry.

| Feature | Stoughton Intermodal Container | Traditional Containers |

|---|---|---|

| Length | 53 ft | 53 ft |

| Internal Width | 100.375 inches | ~98 inches |

| Volume Capacity | 262 cubic feet | ~246 cubic feet |

| Weight | Lighter due to materials | Heavier with steel |

| Material | Composite plate-style design | Corrugated steel |

| Maintenance Needs | Reduced due to durability | Higher due to corrosion |

Quotes Highlighting Commitment to Innovation and Partnerships

Stoughton Trailers is at the forefront of innovation in the transportation industry, as illustrated by key insights from their leadership:

-

Pat Gunn, Vice President of Sales – Intermodal at Stoughton Trailers, emphasizes the company’s dedication to customer-centric design:

“At Stoughton, we have always focused on building equipment that delivers a tangible advantage to our customers. This new intermodal container sets a higher standard in the market—giving carriers the durability they expect with the added capacity that drives real bottom-line success.”

-

Paul Sniegocki, Executive Vice President, Engineering and Chief Technology Officer at Clarience Technologies, speaks to the collaborative efforts that enhance innovation within the sector:

“Innovation doesn’t happen in isolation—it happens through strong partnerships and shared expertise, which allows us to accelerate the pace of innovation in the transportation industry. At Clarience Technologies, our unique ability to integrate best-in-class technologies across our team of companies, alongside trusted OE, fleet, and industry partners, allows us to develop future-ready solutions.”

-

Further commenting on the development of a smart chassis, Sniegocki noted the importance of collaboration:

“The smart chassis project is an excellent example of how collaboration and innovation improve safety and visibility with solutions for industry and customer problems.”

These quotes highlight Stoughton Trailers’ commitment to pushing the boundaries of equipment design and fostering partnerships that drive substantial advancements in the intermodal transportation industry.

Case Studies on Smart Chassis Designs in Intermodal Transportation

Recent advancements in smart chassis designs have significantly impacted intermodal transportation by enhancing efficiency, safety, and automation. Below are several case studies and analyses highlighting these developments:

-

Stoughton Trailers’ Smart Chassis and Intermodal Container Innovations

Source: Transport Topics

Date: September 17, 2025

Summary: Stoughton Trailers introduced a 53-foot domestic container with a composite plate design, offering increased durability and 6.5% more internal volume compared to traditional containers. Additionally, their next-generation Smart Chassis features the Auto Connect system, enabling automated coupling of pneumatic and electrical lines in seven seconds without driver intervention. This innovation enhances operational efficiency and supports the transition toward autonomous operations. [ttnews.com] -

TRAC Intermodal’s Fleet Modernization Amid Chassis Supply Challenges

Source: TRAC Intermodal

Date: 2025

Summary: Facing increased demand and supply constraints, TRAC Intermodal invested over $1 billion since 2015 in fleet modernization. This included refurbishing existing chassis through their Blue Edge Chassis program, enhancing equipment availability and reliability. Customers reported improved operational flexibility and reduced downtime, highlighting the program’s effectiveness in addressing supply chain challenges. [tracintermodal.com] -

Impact of Telematics on Intermodal Chassis Management

Source: CIE Manufacturing

Date: 2025

Summary: The integration of telematics into intermodal chassis management has transformed fleet operations by providing real-time location tracking, predictive maintenance alerts, and enhanced dispatching capabilities. These technologies have led to reduced downtime, improved asset utilization, and increased operational efficiency, demonstrating the significant advantages of digitalization in intermodal transportation. [ciemanufacturing.com] -

Digital Freight Transport Platforms in Intermodal Case Study

Source: Electronic Markets

Date: May 30, 2025

Summary: A study investigated the adoption drivers and barriers of digital freight transport platforms in intermodal transportation. It identified 30 factors influencing adoption, including concerns about market transparency and interface standardization among service providers, while service demanders favored these attributes. The research provided insights into fostering platform adoption to enhance supply chain automation. [link.springer.com]

These case studies illustrate the transformative effects of smart chassis designs and automated systems in modern intermodal transportation, emphasizing improvements in efficiency, safety, and the integration of advanced technologies. In particular, Stoughton Trailers has made significant strides with their smart chassis design. Their innovations, such as the Auto Connect system for automated coupling and enhanced durability through composite materials, greatly enhance operational efficiency.

Moreover, TRAC Intermodal’s modernization efforts and the integration of telematics by CIE Manufacturing show how these advancements contribute to better fleet management and reduced downtime, highlighting the essential role of technology in addressing the challenges of intermodal transportation. Finally, the adoption of digital freight transport platforms has been identified as a pivotal factor in enhancing supply chain automation, enabling a smoother integration between various transportation modes. Together, these advancements are reshaping the intermodal transportation landscape, illustrating that smart chassis designs are crucial for improved efficiency and responsiveness in the logistics sector.

Conclusion

Stoughton Trailers’ recent innovations in intermodal container and smart chassis design mark a significant leap forward for the trucking industry. By reintroducing a 53-foot intermodal container with advanced features such as a wider internal width and increased volume capacity, Stoughton is setting a new benchmark for efficiency and transportation logistics. These advancements are not just numbers on a spreadsheet; they represent a tangible solution to age-old challenges such as maximizing cargo space and reducing the frequency of trips.

The introduction of smart chassis technology further highlights Stoughton’s commitment to enhancing operational efficiency through automation and connectivity. Innovations like the Auto Connect system not only streamline operations but also improve safety and visibility, which are crucial in today’s fast-paced supply chain environment. As the transportation landscape evolves, these features position Stoughton Trailers as a forward-thinking leader poised to adapt to emerging market demands and regulatory requirements.

Looking to the future, the implications of Stoughton’s innovations extend beyond just their own company. As the trucking industry continues to grapple with labor shortages, environmental concerns, and the need for greater productivity, these advancements may well dictate new industry standards. Companies adopting similar technological solutions are likely to gain a competitive edge while enhancing their sustainability efforts. Stoughton Trailers is not only paving the way for operational efficiency but also leading the charge toward a more innovative, resilient, and environmentally focused future in the transportation sector.

In summary, the strides made by Stoughton Trailers are a testament to their dedication to innovation and excellence, heralding a new era for the trucking industry focused on enhanced capacity, sustainability, and adaptability—a roadmap for success in an ever-evolving landscape.

Partnerships Enhancing Innovation in Stoughton’s Smart Chassis and Containers

Stoughton Trailers has strategically partnered with leading companies such as Clarience Technologies to revolutionize their smart chassis and intermodal container capabilities. These collaborations aim to leverage advanced technologies and shared expertise to create innovative solutions that meet the evolving needs of the transportation industry.

Collaborative Innovations

Through partnerships with Clarience Technologies, Stoughton has focused on incorporating cutting-edge technologies into their products. For instance, the integration of AI-driven systems within their smart chassis enhances operational efficiency by allowing for automated coupling and real-time monitoring of systems. This means the chassis can adapt to varying loads and optimize performance without the need for constant human intervention.

Moreover, the use of advanced materials and designs, developed in collaboration with industry experts, ensures that their intermodal containers are durable and lightweight, promoting better fuel efficiency and reducing maintenance costs.

Benefits of the Partnerships

The positive impact of these partnerships can be measured through several key benefits:

- Increased Efficiency: By optimizing operational processes through smart technologies, companies can reduce downtimes and enhance the reliability of transport services.

- Enhanced Safety: Innovations such as integrated IoT sensors and telematics improve safety measures by providing real-time alerts and monitoring, ensuring safer transport operations.

- Cost Savings: Through collaboration, Stoughton can develop cost-effective solutions that decrease maintenance needs and enhance the lifecycle of their products, ultimately leading to lower total costs for customers.

Future Developments in Intermodal Transportation

Looking ahead, ongoing partnerships are likely to yield even more advancements in the smart trucking sector. Potential future developments may include:

- Smart Fleet Management Solutions: Enhanced collaboration could lead to the development of sophisticated fleet management platforms that utilize predictive analytics to streamline logistics.

- Sustainable Practices: With growing emphasis on sustainability, partnerships aimed at developing eco-friendly technologies and materials will likely emerge, reducing the carbon footprint of transportation.

- End-to-End Integration: Future innovations may focus on fully integrating logistics solutions from point of origin to destination, utilizing smart technology for seamless coordination.

In conclusion, Stoughton’s partnerships play a crucial role in shaping the future of intermodal transportation. By continually investing in collaborative efforts with industry leaders, they are not only enhancing their product offerings but also setting new standards for efficiency, safety, and sustainability in the trucking industry.

Summary of Advantages for Fleet Managers and Logistics Operators

- Increased Cargo Capacity: The new 53-ft intermodal container offers 6.5% more internal volume, allowing for more goods to be transported per trip.

- Wider Internal Width: With an internal width of 100.375 inches, the container accommodates larger items, enhancing loading capabilities and reducing handling time.

- Enhanced Durability: Constructed with composite materials and weather-resistant panels, the containers are designed to withstand harsh conditions, reducing repair and maintenance costs over time.

- Smart Chassis Features: The integration of IoT technology enables real-time monitoring of vehicle health and cargo conditions, leading to better maintenance scheduling and fewer unexpected repairs.

- Automated Coupling Systems: With features like Auto Connect, the smart chassis allows for quicker and more efficient coupling of trailers, reducing the time needed for loading and unloading.

- Cost Efficiency: Increased cargo capacity and reduced maintenance needs translate into significant cost savings, allowing logistics operations to lower per-mile costs and enhance profitability.

- Compliance with Standards: The use of hot-dip galvanized steel exceeds safety standards, ensuring reliability in intermodal transport and contributing to a safer logistics environment.

- Sustainability Initiatives: The design minimizes material waste and promotes fuel efficiency, aligning with the industry’s push toward greener transportation solutions.

Visualizing Enhancements in Container Technology

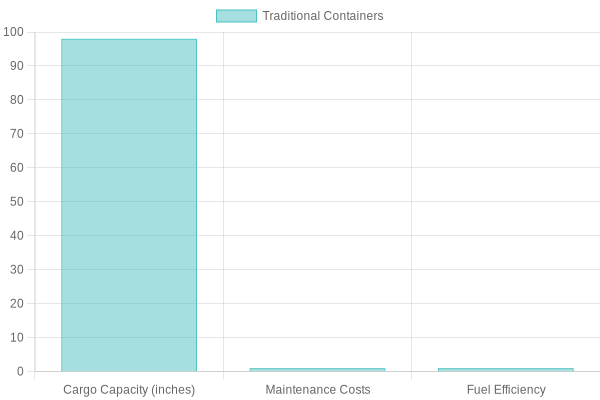

To effectively illustrate the advantages of Stoughton Trailers’ new intermodal containers, the following visuals have been created:

Graph Comparing Operational Efficiencies

Graph comparing cargo capacity, maintenance costs, and fuel efficiency between traditional containers and Stoughton Trailers’ new intermodal container with smart chassis.

Infographic on Cost Savings

Infographic illustrating operational efficiencies and cost savings of Stoughton Trailers’ new intermodal containers compared to traditional models.

Importance of Innovations in Intermodal Transportation

Innovations in intermodal transportation significantly enhance efficiency and profitability for trucking companies. Key developments include:

-

Artificial Intelligence and Machine Learning: Companies integrate AI to optimize route planning, predict maintenance needs, and improve decision-making. For instance, 3SC Solutions launched iTMS, an AI-driven transport management solution.

- Features: Real-time route optimization, predictive analytics to anticipate disruptions.

-

Autonomous Vehicles: Deployment of self-driving trucks is advancing.

- Example: Companies like Aurora Innovation and Kodiak Robotics planning routes between Dallas and Houston.

- Benefits: Counter labor shortages, improve fuel efficiency, adhere to regulations.

-

Blockchain Technology: Adoption of blockchain enhances transparency and traceability.

- Advantages: Automates processes, reduces paperwork, prevents fraud, improves inventory management.

-

Internet of Things and Telematics: Equipping vehicles with IoT sensors for real-time monitoring.

- Benefits: Predictive maintenance, optimized routes, improved safety.

-

Sustainability Initiatives: Transition to electric trucks driven by environmental concerns.

- Outcome: Year-long cost savings from reduced emissions.

Collectively, these innovations contribute to enhanced operational efficiency, reduce costs, and improve profitability for trucking companies engaged in smart logistics and supply chain innovation.

Image representing innovations in intermodal transportation and smart logistics.

Evidence of Stoughton Trailers’ Design Innovations

Stoughton Trailers has made significant strides in intermodal container design with their new 53-foot domestic container, distinguished by its robust specifications and innovative features. This design marks a notable return to the intermodal segment, emphasizing enhanced freight capacity and durability.

Specifications:

- Length: 53 feet

- Internal Width: 100.375 inches (2.375 inches wider than traditional containers)

- Volume Capacity: 262 cubic feet (6.5% more than standard models)

- Materials: Composite plate-style design with weather-resistant bonded sidewall panels, utilizing domestically sourced steel and aluminum, manufactured in Wisconsin.

Capacity Benefits:

The broader internal dimensions of Stoughton’s container provide the ability to carry more cargo per load, significantly boosting operational efficiency. With an additional 262 cubic feet of volume, logistics companies can optimize space utilization, minimizing trips and maximizing payload through transport efficiency.

Durability and Performance:

Stoughton’s innovative use of composite materials and reinforced structural components helps resist damage, leading to decreased repair costs and an extended lifecycle. Moreover, the weather-resistant sidewall panels reduce the risk of corrosion, ensuring longevity and lower maintenance.

Comparison to Traditional Models:

When stacked against conventional corrugated steel containers, which typically have an internal width of about 98 inches, Stoughton’s model offers a significant competitive edge. The additional width and volume enhance loading capabilities.

Furthermore, traditional containers often struggle with corrosion and structural fatigue; Stoughton’s strategic use of hot-dip galvanized steel for structural components not only addresses these issues but also exceeds standards set by the Association of American Railroads (AAR), ensuring compliance and reliability for intermodal transport.

In conclusion, Stoughton Trailers’ 53-foot intermodal container represents a substantial improvement over traditional models, boasting increased capacity, enhanced durability, and advanced construction methodologies that set a new benchmark in the industry.

Introduction

In an ever-evolving trucking industry, Stoughton Trailers stands at the forefront of innovation with its latest advancements in intermodal container and smart chassis design. The company introduces a remarkable 53-foot container boasting an impressive 262 cubic feet of volume, which is 6.5% more than traditional models. This cutting-edge design significantly enhances cargo capacity, reflecting Stoughton’s strategic return to the intermodal segment where innovation meets practical solutions. These advancements promise not only operational efficiency but also a positive impact on workers and the environment, as improved technologies can lead to safer working conditions and reduced emissions. By embracing such innovations, Stoughton Trailers is redefining the standards of intermodal logistics, promising significant advantages for modern supply chain operations.

Importance of Innovations in Intermodal Transportation

Innovations in intermodal transportation significantly enhance efficiency and profitability for trucking companies. Key developments include:

-

Artificial Intelligence and Machine Learning: Companies integrate AI to optimize route planning, predict maintenance needs, and improve decision-making. For instance, 3SC Solutions launched iTMS, an AI-driven transport management solution.

- Features: Real-time route optimization, predictive analytics to anticipate disruptions.

-

Autonomous Vehicles: Deployment of self-driving trucks is advancing.

- Example: Companies like Aurora Innovation and Kodiak Robotics planning routes between Dallas and Houston.

- Benefits: Counter labor shortages, improve fuel efficiency, adhere to regulations.

-

Blockchain Technology: Adoption of blockchain enhances transparency and traceability.

- Advantages: Automates processes, reduces paperwork, prevents fraud, improves inventory management.

-

Internet of Things and Telematics: Equipping vehicles with IoT sensors for real-time monitoring.

- Benefits: Predictive maintenance, optimized routes, improved safety.

-

Sustainability Initiatives: Transition to electric trucks driven by environmental concerns.

- Outcome: Year-long cost savings from reduced emissions.

Collectively, these innovations contribute to enhanced operational efficiency, reduce costs, and improve profitability for trucking companies engaged in intermodal transportation. As these advancements unfold, they offer practical solutions that promise benefits not just for companies but also for the workers who rely on improved systems for their daily tasks.

Evidence of Stoughton Trailers’ Design Innovations

Building on the innovations mentioned, Stoughton Trailers has made significant strides in intermodal container design with their new 53-foot domestic container, distinguished by its robust specifications and innovative features. This design marks a notable return to the intermodal segment, emphasizing enhanced freight capacity and durability.

Specifications:

- Length: 53 feet

- Internal Width: 100.375 inches (2.375 inches wider than traditional containers)

- Volume Capacity: 262 cubic feet (6.5% more than standard models)

- Materials: Composite plate-style design with weather-resistant bonded sidewall panels, utilizing domestically sourced steel and aluminum, manufactured in Wisconsin.

Capacity Benefits:

The broader internal dimensions of Stoughton’s container provide the ability to carry more cargo per load, significantly boosting operational efficiency. This means workers can handle fewer loads, decreasing physical strain and optimizing productivity. With an additional 262 cubic feet of volume, logistics companies can optimize space utilization, minimizing trips and maximizing payload.

Durability and Performance:

Stoughton’s innovative use of composite materials and reinforced structural components helps resist damage, leading to decreased repair costs and an extended lifecycle. Moreover, the weather-resistant sidewall panels reduce the risk of corrosion, ensuring longevity and lower maintenance, thus contributing to sustainable practices within the industry.

Comparison to Traditional Models:

When stacked against conventional corrugated steel containers, which typically have an internal width of about 98 inches, Stoughton’s model offers a significant competitive edge. The additional width and volume enhance loading capabilities, allowing workers to load and unload goods more efficiently.

Furthermore, traditional containers often struggle with corrosion and structural fatigue; Stoughton’s strategic use of hot-dip galvanized steel for structural components not only addresses these issues but also exceeds standards set by the Association of American Railroads (AAR), ensuring compliance and reliability for intermodal transport.

In conclusion, the advancements made by Stoughton Trailers in its 53-foot intermodal container represent a substantial improvement over traditional models. These innovations in container design not only enhance capacity and durability but also echo a commitment to a more efficient and sustainable transportation system that ultimately benefits workers and the environment.