In an era where efficiency and sustainability are paramount, intermodal transport stands out as a transformative solution within the logistics and supply chain landscape. This innovative approach leverages multiple modes of transportation, allowing goods to move seamlessly across land and sea, significantly enhancing distribution capabilities.

At the forefront of this movement is Stoughton Trailers, a company renowned for its commitment to advancing intermodal technology. Their latest introduction, a groundbreaking intermodal container paired with a smart chassis, not only redefines industry standards but also sets a new benchmark for operational excellence. This remarkable container boasts enhanced capacity and cutting-edge features, underscoring Stoughton Trailers’ role as a trailblazer in the intermodal freight sector.

Join us as we explore the intricacies of these advancements and their potential to reshape the future of transport logistics.

Customer Benefits of the New Intermodal Container and Smart Chassis Design

The innovations in Stoughton Trailers’ new 53-ft intermodal container and smart chassis design offer substantial benefits tailored to customer needs, emphasizing efficiency and capacity improvements. As noted by Pat Gunn, vice-president of sales – intermodal at Stoughton Trailers:

“At Stoughton, we have always focused on building equipment that delivers a tangible advantage to our customers.”

This commitment is reflected in several key areas that enhance the overall customer experience:

-

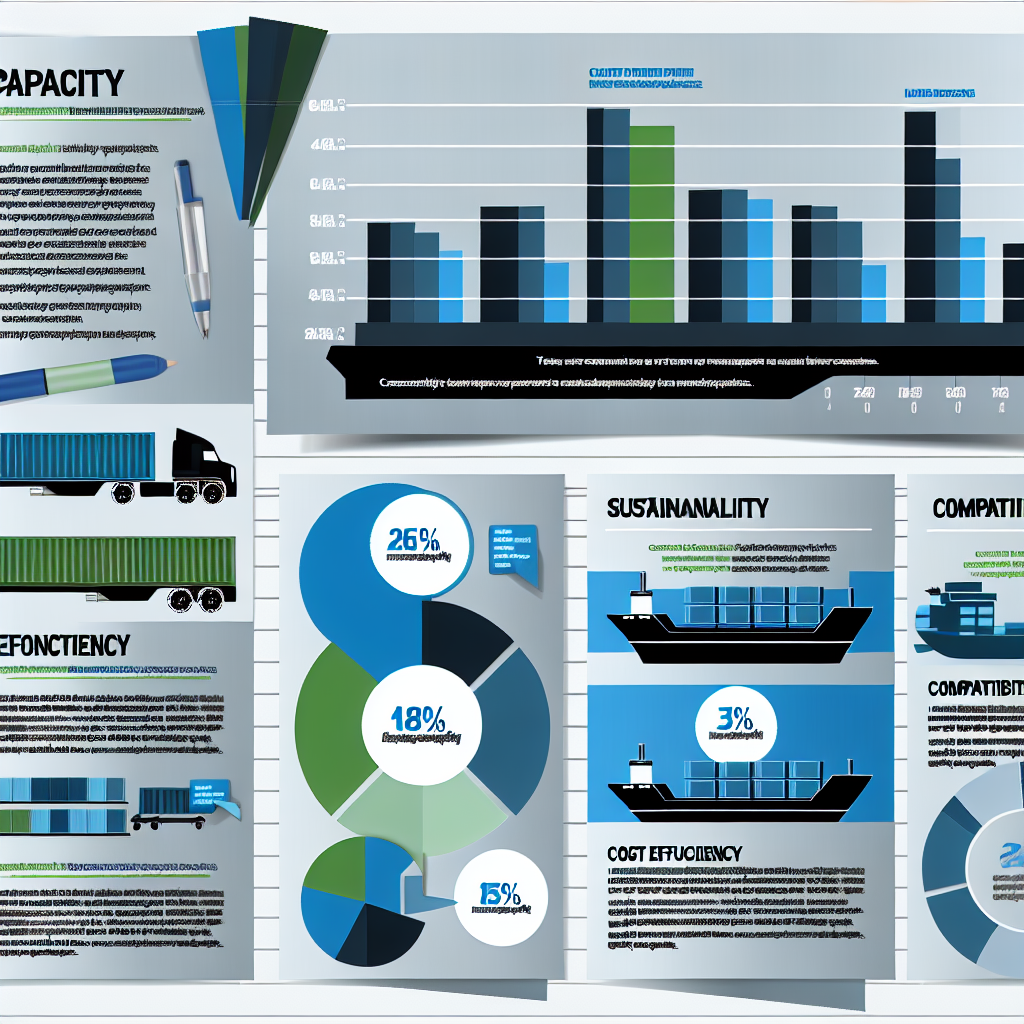

Enhanced Capacity and Volume

- Offers 262 cubic feet more volume than traditional corrugated steel containers.

- Allows customers to transport more goods in a single trip.

- Reduces logistics costs through fewer shipments and better resource utilization.

-

Improved Efficiency with Smart Features

- Equipped with AI image recognition cameras and sensor systems.

- Provides real-time monitoring and maintenance alerts to minimize delays.

- Ensures equipment is road-ready, addressing fleet operators’ primary concerns.

-

Seamless Compatibility in Transportation

- Ensures compatibility across various transport modes, including truck, rail, and ship.

- Improves supply chain agility, allowing for quick responses to market changes.

-

Support for Sustainability Goals

- Reduces the number of trips needed to transport the same volume of goods.

- Lowers carbon footprint, aligning with global movements towards greener logistics practices.

In conclusion, Stoughton Trailers’ new innovations are designed not just to enhance their offerings but to directly contribute to the success of their customers. Through increased capacity, superior efficiency, and sustainable practices, they truly deliver on the promise of providing a tangible advantage in today’s competitive landscape.

Illustration of the new 53-ft intermodal container designed by Stoughton Trailers, in use on a truck to demonstrate intermodal transport capabilities.

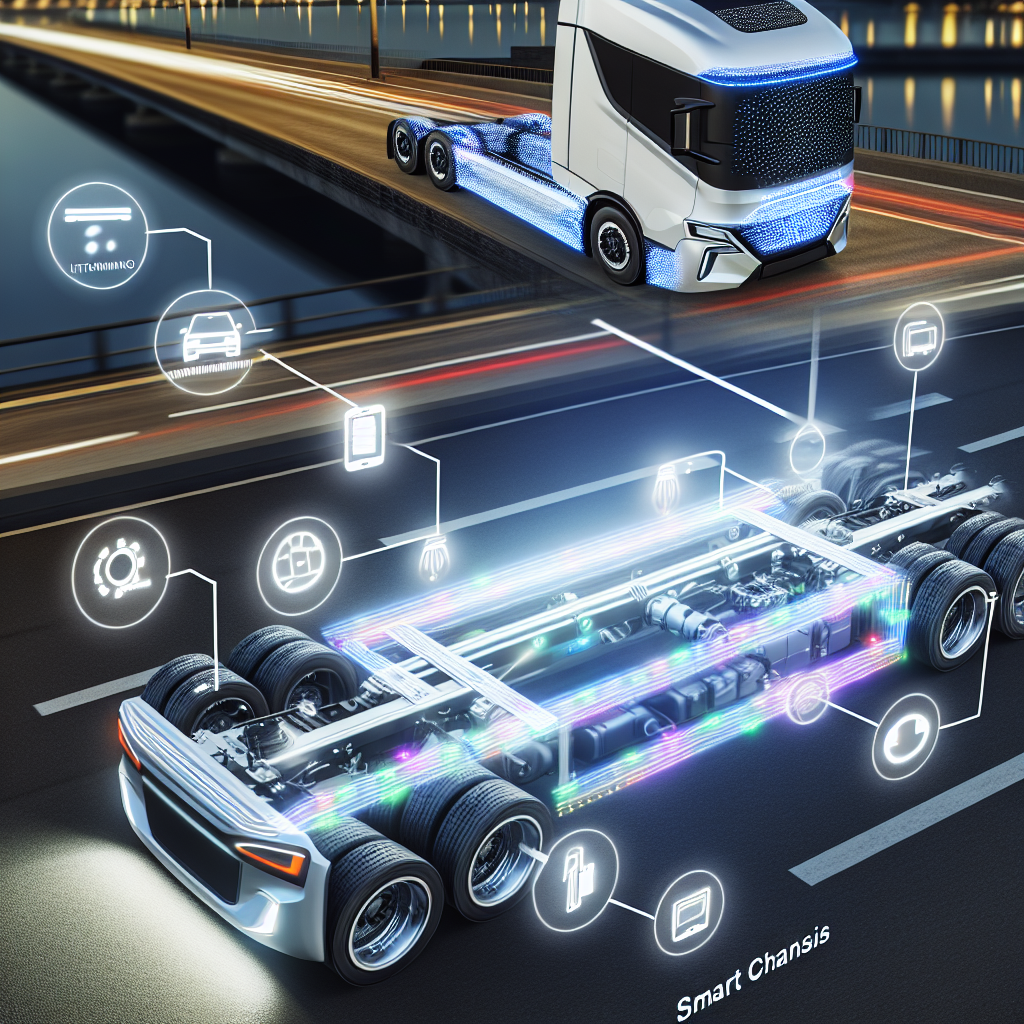

A visual representation of smart chassis technology, featuring automated tire inflation systems, sensors monitoring road conditions, and an operational chassis on a modern truck.

Technological Innovations in Intermodal Containers

The new intermodal container designed by Stoughton Trailers stands as a testament to the integration of cutting-edge technology in freight operations. Equipped with advanced AI image recognition cameras and sensor systems, this design not only revolutionizes the container itself but also significantly enhances operational efficiency across logistics networks.

AI Image Recognition Cameras

The incorporation of AI-based image recognition systems allows for the seamless identification of containers as they move through ports and terminals. With a dataset comprising over 35,000 annotated instances, these systems leverage sophisticated AI pipelines to detect and validate IDs under various conditions and angles. This advancement improves speed and accuracy in container handling, effectively reducing turnaround times in busy freight environments.

Advanced Optical Character Recognition

Companies such as Camco Technologies have pioneered AI-enabled cameras that process essential data using high-resolution imaging and embedded AI processors. This technology employs convolutional neural networks to expedite data capture from containers and trucks, resulting in enhanced operational precision.

Enhanced Yard Management Systems

Platforms like EAIGLE combine AI and machine vision technologies to track vehicles and assets in logistics yards. By providing real-time data and analytics, these systems ensure that freight operations are organized and streamlined, ultimately enhancing productivity and reducing costs.

Automated Damage Detection

Automated systems powered by AI can quickly inspect containers for any damages, enabling operators to address issues without disrupting the overall flow of logistics operations. Such proactive measures not only safeguard against operational delays but also enhance container lifespan and reliability.

Smart Containers with IoT Sensors

Furthermore, the introduction of IoT sensors within containers offers real-time monitoring of critical parameters such as temperature and humidity. These smart containers ensure that sensitive cargo remains protected throughout transit, thereby increasing supply chain transparency and integrity.

In conclusion, the technological innovations integrated into Stoughton Trailers’ new intermodal container represent a significant leap forward in intermodal freight efficiency. By leveraging AI and advanced sensor technologies, these enhancements ensure smoother operations, reduced logistics costs, and a greater overall return on investment for freight operators ensuring they remain competitive in an ever-evolving industry.

User Adoption of Innovative Intermodal Container Designs

The introduction of new intermodal container designs has ushered in notable changes for shipping companies, leading to tangible benefits in their operations. Here are some key case studies illustrating how these innovations are reshaping the landscape:

-

National Food Distributor Reduces Freight Costs by 22%

A leading national food distributor in Toronto, seeking to combat rising trucking costs and delivery inconsistencies, adopted temperature-controlled intermodal containers for shipments to Vancouver. This strategic switch included utilizing rail for long-haul transport and trucks for local deliveries, leading to impressive outcomes:

- 22% reduction in freight costs

- 18% improvement in on-time deliveries

- Enhanced cold chain performance with fewer logistics touchpoints

The integration of rail provided predictable transit, significantly reducing diesel consumption. Source

“The integration of temperature-controlled intermodal containers allowed us to maintain the integrity of our products while optimizing our shipping costs.”

-

Furniture Retailer Improves Delivery Reliability

A Quebec-based furniture retailer faced recurring shipping delays due to weather and roadway issues. Transitioning to intermodal rail shipping between Montreal and Calgary, alongside short-haul trucking, resulted in:

- 25% lower transportation costs

- 30% decrease in late deliveries

- Improved inventory flow and higher customer satisfaction

Intermodal shipping facilitated more consistent transit scheduling, allowing for improved planning and responsiveness to consumer demand. Source

“Switching to intermodal shipping transformed our delivery reliability, giving us the flexibility we needed during peak seasons.”

-

Clean Tech Manufacturer Gains Shipment Visibility

An Ontario-based clean tech manufacturer needed reliable transport for precision equipment to British Columbia. Collaborating with an intermodal logistics provider, they implemented a plan incorporating GPS tracking and specialized container handling, achieving:

- Real-time shipment visibility

- 40% reduction in cargo damage

- Enhanced production planning and inventory control

This approach allowed for minimizing handling points, thus preserving sensitive equipment integrity during transit. Source

“The GPS tracking system integrated into our shipments has been a game-changer, allowing us unprecedented visibility and control over our logistics.”

-

IKEA’s Intermodal Transformation

IKEA has shifted a significant portion of its North American shipments to intermodal rail, resulting in:

- A 45% reduction in carbon emissions.

- A 25% decrease in transportation costs.

Pia Heidenmark Cook, IKEA’s Chief Sustainability Officer, stated:

“Intermodal transportation is not just environmentally responsible but also makes strong business sense in our operation.”

-

Procter & Gamble’s Network Optimization

Procter & Gamble redesigned its distribution networks utilizing intermodal hubs, achieving substantial savings:

- Annual savings around $100 million.

- 25% reduction in empty miles.

“By redesigning our distribution network to incorporate intermodal strategies, we have not only saved costs but created a more resilient supply chain.”

Challenges in Intermodal Transportation

While intermodal transportation offers numerous benefits, businesses also encounter challenges such as infrastructure limitations, coordination complexity, initial investment requirements, and transit time variability. Companies must navigate these factors to fully realize the benefits of intermodal solutions.

| Feature/Specification | Traditional Corrugated Steel Container | Stoughton Intermodal Container |

|---|---|---|

| Internal Width | 98 inches | 100.375 inches |

| Volume Capacity | ~2,400 cubic feet | ~2,662 cubic feet |

| Weight | Approximately 5,000 lbs | Approximately 5,500 lbs |

| Cargo Handling Method | Manual or Forklift | Automated systems with AI |

| Technology Features | Basic Inventory Tracking | AI Image Recognition, IoT Sensors |

| Durability | Moderate | Enhanced with Smart Chassis |

| Ideal Usage | General Freight | Intermodal Transport |

Partnerships and Collaborations in Chassis Design

Stoughton Trailers has formed strategic partnerships that underscore their commitment to fostering innovation in chassis design and intermodal transportation. A notable collaboration is with Clarience Technologies, which has led to the development of an advanced intelligent chassis that enhances safety, connectivity, and efficiency within the transportation sector.

This intelligent chassis incorporates cutting-edge technologies from Clarience’s subsidiaries. One significant feature is the Electrans Technologies’ Auto Connect system, which automates the coupling of truck and chassis air, electrical, and communication lines in just seven seconds, allowing drivers to remain in the cab. This enhancement promotes operational safety and efficiency.

Some of the key components provided by Clarience Technologies include:

- Road Ready: Offers modular hardware and centralized insights for real-time operational visibility through features like Automatic Tire Inflation Warning and ABS Warning Sensors.

- Rear View Safety (RVS): Equips the system with wired Ethernet and Air Vue wireless camera systems, boosting driver awareness with comprehensive coverage.

- Pressure Systems International (P.S.I.): Supplies an Automatic Tire Inflation System and monitoring technologies that ensure optimal tire health and uptime.

- Truck-Lite: Enhances reliability, safety, and connectivity through advanced LED lighting and monitoring systems.

This collaboration not only aims to improve tractor-trailer communication but also to prepare the industry for future technologies, such as next-generation braking systems and autonomous systems. The intelligent chassis design allows for flexible adoption of technology, enabling fleets to integrate new features progressively.

As Paul Sniegocki, executive vice-president of engineering and chief technology officer at Clarience Technologies, stated, “Innovation doesn’t happen in isolation – it happens through strong partnerships and shared expertise which allows us to accelerate the pace of innovation in the transportation industry.”

Through partnerships like these, Stoughton Trailers is setting new standards in chassis design and intermodal transportation, focusing on enhancing safety, efficiency, and readiness for future advancements.

Evaluation of Current Market Trends in Intermodal Transportation

The intermodal transportation landscape is undergoing a remarkable transformation, driven by technological innovations and evolving market demands. As we move into 2025, several key trends shape this sector, prominently represented by Stoughton Trailers’ recent strides in the industry.

-

Growth Projections

The global intermodal freight transportation market is projected to expand from USD 28.3 billion in 2025 to USD 96.4 billion by 2034, reflecting a compound annual growth rate (CAGR) of 14.6%. Factors contributing to this growth include the rise of e-commerce, increased demand for efficient logistics, and a strong move towards sustainable transport solutions

source. -

Technological Integration & Innovations

Intermodal transportation is increasingly reliant on advanced technologies: the use of AI for real-time logistics optimization, automation of processes, and the application of blockchain for enhanced tracking and transparency are now standard practice. Stoughton Trailers exemplifies this trend with its newly unveiled Smart Chassis, which integrates automation features that improve safety and efficiency while preparing fleets for future advancements in autonomous technology

source.

The company has also introduced a 53-foot intermodal container, designed to be durable and spacious enough to transport larger volumes while ensuring that freight integrity is maintained throughout transit

source. -

Sustainability Trends

As regulatory pressures increase global sustainability measures, the shift from traditional trucking to intermodal solutions is being strongly encouraged. Regulations like the European Union’s commitment to significantly reducing CO2 emissions for heavy-duty vehicles by 2025 and beyond are incentivizing shippers to adopt more eco-friendly practices, thus enhancing intermodal adoption rates

source. -

Strategic Partnerships

Collaborations between companies, such as Stoughton Trailers and Clarience Technologies, are pivotal in integrating new technologies into chassis designs to enhance communication and operational efficiencies. This focus on partnerships illustrates a collective approach within the industry to foster innovation and address contemporary challenges

source.

Future Outlook

The future of intermodal transportation looks promising, characterized by continued technological advancements in automation, AI, and strategic collaborations that hold the potential to reshape operational mechanics. As companies like Stoughton Trailers lead the charge in developing innovative solutions that address both capacity and efficiency, the intermodal sector is poised to become a cornerstone of modern logistics and supply chain management.

Conclusion

Stoughton Trailers’ groundbreaking innovations in intermodal containers and smart chassis design have significantly reshaped the landscape of freight transportation. By introducing a 53-ft intermodal container that offers industry-leading capacity and advanced smart technology, Stoughton Trailers is setting the stage for a more efficient and sustainable future. With an impressive increase in volume, state-of-the-art monitoring capabilities, and enhanced compatibility across transport modes, these new products empower logistics companies to optimize their operations and reduce overall costs.

Moreover, the commitment to sustainability is crucial in today’s logistics environment. By enabling fewer shipments with larger capacities, these innovations contribute to lowering carbon footprints, promoting greener logistics practices. As we look to the future of freight transportation, it is clear that continual innovation will play a vital role. Stoughton Trailers stands at the forefront, demonstrating that advancements in technology not only enhance operational efficiency but also align with broader environmental goals.

As we navigate the complexities of the modern supply chain, let us champion the need for ongoing innovation that drives progress and efficiency in intermodal transportation.

Interested in learning more about how Stoughton Trailers can enhance your logistics operations? Contact us today for more information on our latest products and services.

An infographic that highlights the key benefits of intermodal containers, covering aspects such as capacity, efficiency, sustainability, and compatibility across different transport modes. The illustration visually represents how intermodal containers improve logistics operations and contribute to a reduced carbon footprint.

In an era where efficiency and sustainability are paramount, intermodal transport stands out as a transformative solution within the logistics and supply chain landscape. This innovative approach leverages multiple modes of transportation, allowing goods to move seamlessly across land and sea, significantly enhancing distribution capabilities. At the forefront of this movement is Stoughton Trailers, a company renowned for its commitment to advancing intermodal technology. Their latest introduction, a groundbreaking intermodal container paired with a smart chassis, not only redefines industry standards but also sets a new benchmark for operational excellence. This remarkable container boasts enhanced capacity and cutting-edge features, underscoring Stoughton Trailers’ role as a trailblazer in the intermodal freight sector. Join us as we explore the intricacies of these advancements and their potential to reshape the future of transport logistics.

Customer Benefits of the New Intermodal Container and Smart Chassis Design

The innovations in Stoughton Trailers’ new 53-ft intermodal container and smart chassis design offer substantial benefits tailored to customer needs, emphasizing efficiency and capacity improvements. As noted by Pat Gunn, vice-president of sales – intermodal at Stoughton Trailers:

“At Stoughton, we have always focused on building equipment that delivers a tangible advantage to our customers.”

This commitment is reflected in several key areas that enhance the overall customer experience:

- Enhanced Capacity and Volume

- Offers 262 cubic feet more volume than traditional corrugated steel containers.

- Allows customers to transport more goods in a single trip.

- Reduces logistics costs through fewer shipments and better resource utilization.

- Improved Efficiency with Smart Features

- Equipped with AI image recognition cameras and sensor systems.

- Provides real-time monitoring and maintenance alerts to minimize delays.

- Ensures equipment is road-ready, addressing fleet operators’ primary concerns.

- Seamless Compatibility in Transportation

- Ensures compatibility across various transport modes, including truck, rail, and ship.

- Improves supply chain agility, allowing for quick responses to market changes.

- Support for Sustainability Goals

- Reduces the number of trips needed to transport the same volume of goods.

- Lowers carbon footprint, aligning with global movements towards greener logistics practices.

In conclusion, Stoughton Trailers’ new innovations are designed not just to enhance their offerings but to directly contribute to the success of their customers. Through increased capacity, superior efficiency, and sustainable practices, they truly deliver on the promise of providing a tangible advantage in today’s competitive landscape.

Technological Innovations in Intermodal Containers

The new intermodal container designed by Stoughton Trailers stands as a testament to the integration of cutting-edge technology in freight operations. Equipped with advanced AI image recognition cameras and sensor systems, this design not only revolutionizes the container itself but also significantly enhances operational efficiency across logistics networks.

AI Image Recognition Cameras

The incorporation of AI-based image recognition systems allows for the seamless identification of containers as they move through ports and terminals. With a dataset comprising over 35,000 annotated instances, these systems leverage sophisticated AI pipelines to detect and validate IDs under various conditions and angles. This advancement improves speed and accuracy in container handling, effectively reducing turnaround times in busy freight environments.

Advanced Optical Character Recognition

Companies such as Camco Technologies have pioneered AI-enabled cameras that process essential data using high-resolution imaging and embedded AI processors. This technology employs convolutional neural networks to expedite data capture from containers and trucks, resulting in enhanced operational precision.

Enhanced Yard Management Systems

Platforms like EAIGLE combine AI and machine vision technologies to track vehicles and assets in logistics yards. By providing real-time data and analytics, these systems ensure that freight operations are organized and streamlined, ultimately enhancing productivity and reducing costs.

Automated Damage Detection

Automated systems powered by AI can quickly inspect containers for any damages, enabling operators to address issues without disrupting the overall flow of logistics operations. Such proactive measures not only safeguard against operational delays but also enhance container lifespan and reliability.

Smart Containers with IoT Sensors

Furthermore, the introduction of IoT sensors within containers offers real-time monitoring of critical parameters such as temperature and humidity. These smart containers ensure that sensitive cargo remains protected throughout transit, thereby increasing supply chain transparency and integrity.

In conclusion, the technological innovations integrated into Stoughton Trailers’ new intermodal container represent a significant leap forward in intermodal freight efficiency. By leveraging AI and advanced sensor technologies, these enhancements ensure smoother operations, reduced logistics costs, and a greater overall return on investment for freight operators ensuring they remain competitive in an ever-evolving industry.

User Adoption of Innovative Intermodal Container Designs

The introduction of new intermodal container designs has ushered in notable changes for shipping companies, leading to tangible benefits in their operations. Here are some key case studies illustrating how these innovations are reshaping the landscape:

- National Food Distributor Reduces Freight Costs by 22%

A leading national food distributor in Toronto, seeking to combat rising trucking costs and delivery inconsistencies, adopted temperature-controlled intermodal containers for shipments to Vancouver. This strategic switch included utilizing rail for long-haul transport and trucks for local deliveries, leading to impressive outcomes:

- 22% reduction in freight costs

- 18% improvement in on-time deliveries

- Enhanced cold chain performance with fewer logistics touchpoints

The integration of rail provided predictable transit, significantly reducing diesel consumption. Source

“The integration of temperature-controlled intermodal containers allowed us to maintain the integrity of our products while optimizing our shipping costs.”

- Furniture Retailer Improves Delivery Reliability

A Quebec-based furniture retailer faced recurring shipping delays due to weather and roadway issues. Transitioning to intermodal rail shipping between Montreal and Calgary, alongside short-haul trucking, resulted in:

- 25% lower transportation costs

- 30% decrease in late deliveries

- Improved inventory flow and higher customer satisfaction

Intermodal shipping facilitated more consistent transit scheduling, allowing for improved planning and responsiveness to consumer demand. Source

“Switching to intermodal shipping transformed our delivery reliability, giving us the flexibility we needed during peak seasons.”

- Clean Tech Manufacturer Gains Shipment Visibility

An Ontario-based clean tech manufacturer needed reliable transport for precision equipment to British Columbia. Collaborating with an intermodal logistics provider, they implemented a plan incorporating GPS tracking and specialized container handling, achieving:

- Real-time shipment visibility

- 40% reduction in cargo damage

- Enhanced production planning and inventory control

This approach allowed for minimizing handling points, thus preserving sensitive equipment integrity during transit. Source

“The GPS tracking system integrated into our shipments has been a game-changer, allowing us unprecedented visibility and control over our logistics.”

- IKEA’s Intermodal Transformation

IKEA has shifted a significant portion of its North American shipments to intermodal rail, resulting in:

- A 45% reduction in carbon emissions.

- A 25% decrease in transportation costs.

Pia Heidenmark Cook, IKEA’s Chief Sustainability Officer, stated:

“Intermodal transportation is not just environmentally responsible but also makes strong business sense in our operation.”

- Procter & Gamble’s Network Optimization

Procter & Gamble redesigned its distribution networks utilizing intermodal hubs, achieving substantial savings:

- Annual savings around $100 million.

- 25% reduction in empty miles.

“By redesigning our distribution network to incorporate intermodal strategies, we have not only saved costs but created a more resilient supply chain.”

Challenges in Intermodal Transportation

While intermodal transportation offers numerous benefits, businesses also encounter challenges such as infrastructure limitations, coordination complexity, initial investment requirements, and transit time variability. Companies must navigate these factors to fully realize the benefits of intermodal solutions.

| Feature/Specification | Traditional Corrugated Steel Container | Stoughton Intermodal Container |

|---|---|---|

| Internal Width | 98 inches | 100.375 inches |

| Volume Capacity | ~2,400 cubic feet | ~2,662 cubic feet |

| Weight | Approximately 5,000 lbs | Approximately 5,500 lbs |

| Cargo Handling Method | Manual or Forklift | Automated systems with AI |

| Technology Features | Basic Inventory Tracking | AI Image Recognition, IoT Sensors |

| Durability | Moderate | Enhanced with Smart Chassis |

| Ideal Usage | General Freight | Intermodal Transport |

Partnerships and Collaborations in Chassis Design

Stoughton Trailers has formed strategic partnerships that underscore their commitment to fostering innovation in chassis design and intermodal transportation. A notable collaboration is with Clarience Technologies, which has led to the development of an advanced intelligent chassis that enhances safety, connectivity, and efficiency within the transportation sector.

This intelligent chassis incorporates cutting-edge technologies from Clarience’s subsidiaries. One significant feature is the Electrans Technologies’ Auto Connect system, which automates the coupling of truck and chassis air, electrical, and communication lines in just seven seconds, allowing drivers to remain in the cab. This enhancement promotes operational safety and efficiency.

Some of the key components provided by Clarience Technologies include:

- Road Ready: Offers modular hardware and centralized insights for real-time operational visibility through features like Automatic Tire Inflation Warning and ABS Warning Sensors.

- Rear View Safety (RVS): Equips the system with wired Ethernet and Air Vue wireless camera systems, boosting driver awareness with comprehensive coverage.

- Pressure Systems International (P.S.I.): Supplies an Automatic Tire Inflation System and monitoring technologies that ensure optimal tire health and uptime.

- Truck-Lite: Enhances reliability, safety, and connectivity through advanced LED lighting and monitoring systems.

This collaboration not only aims to improve tractor-trailer communication but also to prepare the industry for future technologies, such as next-generation braking systems and autonomous systems. The intelligent chassis design allows for flexible adoption of technology, enabling fleets to integrate new features progressively.

As Paul Sniegocki, executive vice-president of engineering and chief technology officer at Clarience Technologies, stated, “Innovation doesn’t happen in isolation – it happens through strong partnerships and shared expertise which allows us to accelerate the pace of innovation in the transportation industry.”

Through partnerships like these, Stoughton Trailers is setting new standards in chassis design and intermodal transportation, focusing on enhancing safety, efficiency, and readiness for future advancements.

Evaluation of Current Market Trends in Intermodal Transportation

The intermodal transportation landscape is undergoing a remarkable transformation, driven by technological innovations and evolving market demands. As we move into 2025, several key trends shape this sector, prominently represented by Stoughton Trailers’ recent strides in the industry.

- Growth Projections

The global intermodal freight transportation market is projected to expand from USD 28.3 billion in 2025 to USD 96.4 billion by 2034, reflecting a compound annual growth rate (CAGR) of 14.6%. Factors contributing to this growth include the rise of e-commerce, increased demand for efficient logistics, and a strong move towards sustainable transport solutions Source.

- Technological Integration & Innovations

Intermodal transportation is increasingly reliant on advanced technologies: the use of AI for real-time logistics optimization, automation of processes, and the application of blockchain for enhanced tracking and transparency are now standard practice. Stoughton Trailers exemplifies this trend with its newly unveiled Smart Chassis, which integrates automation features that improve safety and efficiency while preparing fleets for future advancements in autonomous technology Source.

The company has also introduced a 53-foot intermodal container, designed to be durable and spacious enough to transport larger volumes while ensuring that freight integrity is maintained throughout transit Source.

- Sustainability Trends

As regulatory pressures increase global sustainability measures, the shift from traditional trucking to intermodal solutions is being strongly encouraged. Regulations like the European Union’s commitment to significantly reducing CO2 emissions for heavy-duty vehicles by 2025 and beyond are incentivizing shippers to adopt more eco-friendly practices, thus enhancing intermodal adoption rates Source.

- Strategic Partnerships

Collaborations between companies, such as Stoughton Trailers and Clarience Technologies, are pivotal in integrating new technologies into chassis designs to enhance communication and operational efficiencies. This focus on partnerships illustrates a collective approach within the industry to foster innovation and address contemporary challenges Source.

Future Outlook

The future of intermodal transportation looks promising, characterized by continued technological advancements in automation, AI, and strategic collaborations that hold the potential to reshape operational mechanics. As companies like Stoughton Trailers lead the charge in developing innovative solutions that address both capacity and efficiency, the intermodal sector is poised to become a cornerstone of modern logistics and supply chain management.

Conclusion

Stoughton Trailers’ groundbreaking innovations in intermodal containers and smart chassis design have significantly reshaped the landscape of freight transportation. By introducing a 53-ft intermodal container that offers industry-leading capacity and advanced smart technology, Stoughton Trailers is setting the stage for a more efficient and sustainable future. With an impressive increase in volume, state-of-the-art monitoring capabilities, and enhanced compatibility across transport modes, these new products empower logistics companies to optimize their operations and reduce overall costs.

Moreover, the commitment to sustainability is crucial in today’s logistics environment. By enabling fewer shipments with larger capacities, these innovations contribute to lowering carbon footprints, promoting greener logistics practices. As we look to the future of freight transportation, it is clear that continual innovation will play a vital role. Stoughton Trailers stands at the forefront, demonstrating that advancements in technology not only enhance operational efficiency but also align with broader environmental goals. As we navigate the complexities of the modern supply chain, let us champion the need for ongoing innovation that drives progress and efficiency in intermodal transportation.

Interested in learning more about how Stoughton Trailers can enhance your logistics operations? Contact us today for more information on our latest products and services.