Commercial trucks play a pivotal role in the global economy as vital components of supply chains, responsible for the transportation of goods across various industries. Understanding what constitutes a commercial truck is essential, as it not only informs procurement decisions but also enhances operational effectiveness in logistics, construction, and delivery services. This article delves into the classification and types of commercial trucks, their indispensable roles in logistics and supply chains, and the crucial design and compliance standards governing their operations. By exploring these facets, logistics and freight company owners, construction and mining procurement teams, and small business owners with delivery fleets will gain valuable insights into optimizing their operational strategies.

The Backbone on Wheels: Decoding Commercial Truck Classifications and Their Role in Modern Freight

Freight moves through a system of classifications, weights, and configurations that guide every fleet decision. A commercial truck is a purpose-built tool for transporting goods or people as part of a business operation, not a private vehicle. The framework starts with GVWR-based tiers (light-duty, medium-duty, and heavy-duty), each associated with licensing, hours of service, and maintenance requirements. Vehicles are distinguished by tractor-trailer versus single-unit setups, and by semi-trailer versus full trailer hitching geometry, which affects load handling and route viability. Cargo type and operating environment shape choices from box and walk-in vans to refrigerated and specialized service trucks. Regulation, infrastructure, and market dynamics together influence fleet strategy, from trailer orders to route design. By viewing classification as a practical toolkit, operators can optimize payload, reliability, and total cost of ownership while staying compliant with safety and environmental standards.

Load-Bearing Liaisons: Understanding What a Commercial Truck Means for Modern Supply Chains

A commercial truck is more than a vehicle with a big engine and a flatbed. It is a deliberately engineered link in a vast network that moves raw materials, components, finished goods, and everything in between from producer to consumer. In the most practical sense, a commercial truck is a vehicle designed and used for business operations centered on the transport of goods or cargo. It sits within the broader category of commercial vehicles, a classification that international standards refer to when distinguishing vehicles used for transporting people or goods from personal passenger cars. This distinction matters because the truck is not a private conveyance; it is a business asset tasked with reliability, payload capacity, and consistent performance under demanding conditions. When we ask what a commercial truck means, we are really asking what purpose a vehicle serves within a system that values speed, safety, and the predictable movement of material goods across cities, regions, and countries.

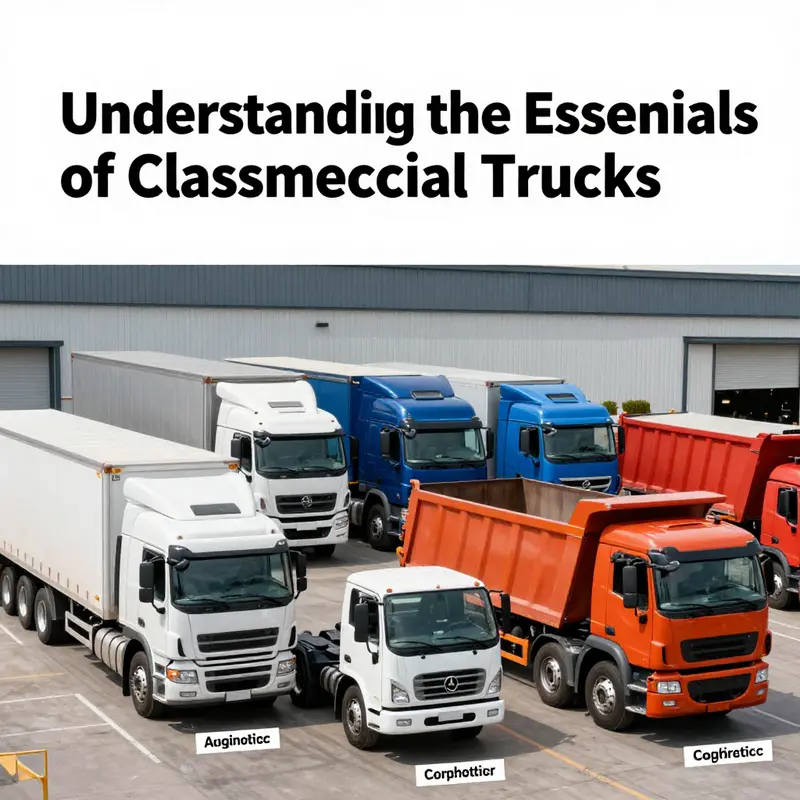

The term encompasses a family of machines designed to fulfill a shared mission: carrying cargo. Trucks come in several forms, each tailored to different logistics needs and operating environments. Tractor-trailers, commonly known as semi-trucks, pull large trailers and are built for long-haul freight across interstate or cross-country routes. Their combination of a powerful tractor and a substantial trailer enables them to move massive quantities of goods efficiently, bridging producers and distributors with minimal stops. Delivery trucks, smaller and more maneuverable, handle local and regional logistics, delivering goods to stores, warehouses, and e-commerce fulfillment centers. They are the backbone of urban and suburban supply chains, where time windows, cold chains, and last-mile constraints influence the design and dispatch of every route.

Dump trucks, or self-unloading trucks, tackle the heavy work of construction and mining. They haul bulk materials such as gravel, sand, and debris, often in environments that demand rugged durability and straightforward unloading mechanisms. Cargo vans and box trucks, compact yet versatile, are favored by small businesses, service fleets, and regional distributors. They excel at door-to-door or curbside deliveries, especially in dense neighborhoods where access and parking challenge larger vehicles. Specialized trucks round out the fleet with capabilities tailored to distinct cargo types: refrigerated or reefers for temperature-sensitive items, tanker trucks for liquids and fuels, and flatbed trucks for oversized or irregular loads that require secure strapping and flexible bed configurations.

This assortment of forms reflects a broader truth about what a commercial truck means in practice: a vehicle optimized for the economics of business transport. The truck is designed not only to carry weight but to do so reliably, safely, and with an eye toward efficient fuel use and downstream performance. Its build emphasizes the durability required to endure hours of operation, the payload capacity needed to meet shift-by-shift demand, and the practical realities of scheduling in a global economy. In many ways, the truck is a mobile warehouse, a power unit that translates planning and coordination into tangible movement of goods.

The role of commercial trucks extends far beyond the physical act of moving items. They are an integral part of the supply chain’s rhythm, connecting suppliers, manufacturers, distributors, retailers, and end consumers. In modern networks, most products travel a road segment at some point, even if they arrive at a port or airport before switching to ships or aircraft for the first or last mile. The truck’s ability to operate across diverse geographies makes it uniquely suited to adapt to congestion, urban constraints, and varying market demands. It is the enabler of just-in-time inventories, the shield against stockouts, and a critical factor in meeting consumer expectations for speed and reliability. When businesses ask what they should count on in a logistics plan, they are asking questions about people, processes, and vehicles—especially trucks—because those are the levers that translate strategy into throughput.

A close look at the impact of commercial trucks on the United States economy reveals why this asset class matters so much. Available data show that trucks transport roughly three-quarters of all goods consumed in the country. The scale is immense: drivers collectively travel hundreds of billions of miles each year, and the volume of cargo moved reflects the daily cadence of households, factories, farms, and retailers. This performance is not accidental; it is the outcome of a carefully balanced system of fleets, routes, maintenance, and labor. The numbers illuminate a wider truth: trucks are the backbone of domestic distribution. They are the essential thread that connects the first mile of supply to the last mile of delivery, tying together the start of a production cycle with the moment a consumer places an order on a shelf or a doorstep.

To appreciate the breadth of a commercial truck’s function, it helps to consider the supply chain as a living organism with multiple organs coordinating. Ports and inland terminals are the lungs that inhale and exhale goods; rail and ocean carriers shuttle large volumes efficiently over long distances; warehouses act as the nervous system that senses demand and orchestrates inventory. In this ecosystem, trucks are the muscular limbs that push movement into motion. They handle the delicate balance between speed and capacity, ensuring that products reach their destinations in a predictable time frame, even when conditions on the road are less than ideal. The practical reality is that without trucks, the flow of goods would stall at the margins, tensions would rise in inventory management, and delivery promises would slip. This is why the trucking sector has become so central to global and domestic trade alike.

Technological evolution has only sharpened the truck’s utility. Modern commercial vehicles increasingly come equipped with GPS navigation, telematics, and real-time data analytics. These tools empower fleet managers to optimize routes, monitor vehicle performance, and foresee maintenance needs before a breakdown disrupts service. The result is more efficient fuel consumption, lower emissions per ton-mile, and shorter lead times. In practice, such technology translates into a fleet that can respond with greater agility to demand spikes, port congestion, or weather-related disruptions. The combination of rugged design and digital intelligence makes the commercial truck a flexible instrument that can be repurposed as market conditions shift.

In addition to efficiency gains, the evolving regulatory landscape shapes how trucks operate. Emissions standards, safety rules, weight limits, and hours-of-service regulations all influence design choices and daily planning. Fleet operators and drivers must stay current with changes, which can alter everything from engine technology to scheduling software. The net effect is a transportation system that remains adaptable, with trucks at the center of compliance and performance. This alignment between policy, technology, and operations helps explain why the commercial truck endures as the preferred mode of freight transport for a broad range of cargo and routes.

From a demand perspective, trucks perform across a spectrum of needs. For long-haul freight, the tractor-trailer configuration offers high payload and efficient economies of scale over great distances. In urban corridors, delivery trucks navigate dense traffic, loading zones, and tight curb space to bring goods to retailers and homes. In construction and resource extraction, dump trucks handle heavy volumes of bulk materials, while reefers keep perishable commodities within safe temperature ranges during transit. The versatility of the truck—its ability to adapt to different cargo types, loading requirements, and timetables—helps explain why it remains indispensable even as other modes of transport evolve. When planners forecast supply chain performance, they typically weigh the reliability and reach of trucking alongside rail, ocean, air, and intermodal options. The conclusion is clear: commercial trucks will remain a central node in the network many years into the future.

A practical reminder of the scale involved comes from consistent industry metrics. In the United States, trucking carries about 72 percent of all goods; the network functionally relies on tens of thousands of drivers who accumulate enormous annual mileages and cargo tonnages. This reality reinforces a simple insight: the trucking sector underpins both everyday commerce and broader economic stability. When supply chains tighten, it is the trucks that often keep product flowing, particularly in the last mile where delivery speed and reliability drive consumer satisfaction. The operational challenge, of course, lies in balancing capacity with demand, maintaining equipment, and ensuring driver welfare in a labor market that is often tight and strategically important for fleet performance. These dynamics create a living, breathing system where each vehicle, route, and decision echoes through manufacturing schedules, retail promotions, and consumer readiness.

Against this backdrop, the industry continually tests the limits of efficiency and resilience. Fleet operators optimize dispatching, maintenance intervals, and load planning to reduce empty miles and improve resource utilization. The result is a more sustainable footprint per ton-mile and a stronger ability to absorb disruption. A critical piece of this puzzle is understanding capacity—how much available trucking should be in service, how asset utilization translates into margins, and how market cycles influence investment in equipment and technology. This is where the conversation often returns to the balance of demand and supply, capacity planning, and the strategic choices companies make to weather volatility. An informed view acknowledges both the vital contribution of trucks to everyday life and the ongoing efforts to modernize fleets in ways that reduce cost, risk, and environmental impact. For readers and practitioners seeking a deeper dive into capacity dynamics, a useful lens is to examine the insights on excess capacity in the trucking market, which synthesizes data on utilization, margins, and fleet aging to illuminate how the market can absorb shocks while maintaining service quality. See https://truckplusllc.com/excess-capacity-in-the-trucking-market-insights/ for a contemporary discussion on this topic.

As markets evolve, the role of the commercial truck in supply chains also expands to more sophisticated coordination across geographies. Goods arrive on ships or planes, then transition into trucks for the so-called first mile of distribution and the last leg of delivery to the end customer. The ability to perform this handoff efficiently depends on dependable fleets, favorable weather and road conditions, and the alignment of carriers with shippers’ schedules. The truck becomes a bridge between global and regional networks, offering the flexibility to adjust to shifting demand patterns, inventory policies, and customer expectations. In this sense, the truck is not merely a vehicle; it is a critical operating tool that supports the entire narrative of modern commerce—from the moment a supplier’s order is placed to the moment it lands on a consumer’s doorstep.

These realities also shed light on the human dimension of trucking. The career path of drivers, the training required to ensure safety on diverse roadways, and the personal costs associated with long-haul life—all of these factors influence fleet performance and industry health. The literature and reports tracking job recovery and workforce development in trucking underscore how labor availability shapes capacity and service quality. In short, the commercial truck is the focal point where technology, policy, economics, and human factors converge to keep goods moving in a complex, interconnected world. The chapter that follows will build on this foundation by examining how the truck’s function translates into practical implications for businesses, policymakers, and everyday consumers alike. For now, it is enough to recognize that the meaning of a commercial truck is inseparable from the efficiency of the systems it feeds and the expectations of the markets it serves.

External reference: For official freight statistics and transportation policy data, see the U.S. Department of Transportation at https://www.transportation.gov

Definition, Design, and Compliance: How Commercial Trucks Drive Modern Supply Chains

In the ecosystem of modern commerce, a commercial truck is more than a roadworthy machine. It is a defined instrument of business that translates orders into arrival times, raw materials into finished goods, and regional demand into reliable service. The term itself marks a boundary between vehicles engineered for economic activity and those built for personal mobility. This distinction matters because it signals a specific set of expectations about durability, payload capability, maintenance needs, and, crucially, regulatory oversight. When a fleet scales up or a regional network expands, the choice of truck becomes a strategic decision about how efficiently a business can move weight from point A to point B, how often it can do so, and how safely every mile is traveled on crowded highways or rural byways. In that sense, the commercial truck is a mobile component of a much larger system—the supply chain—that must function with precision even as conditions shift from season to season and from one market to another. The road, in other words, becomes the operating environment that defines the vehicle’s life cycle, from design and manufacture to operation and retirement or replacement.

At the heart of this story is a simple but powerful idea: not all cargo is created equal, and likewise not all roads are created equal. The spectrum of commercial trucks ranges from tractors that pull long, unbroken trailers across continents to nimble vans that sprint through urban canyons delivering parcels. There are heavy-duty workhorses built to haul steel, concrete, and other bulky materials; there are refrigerated units designed to preserve perishables; there are tankers and flatbeds tailored for specialized cargos. Each type emerges from a specific business problem—the need to maximize payload while minimizing handling, to protect cargo from the weather or theft, to cope with varied terrain, to meet a web of regulatory constraints, and to fit into the daily rhythms of a fleet’s operations. In other words, design choices are not abstract engineering fads; they are practical responses to real-world logistics challenges. The result is a family of machines that share a common mission—to move goods reliably—but differ in geometry, weight distribution, powertrain architecture, and regulatory compliance depending on what they are built to carry and where they operate.

The standard-setting frameworks that guide this design are not arbitrary. International benchmarks, such as ISO 3833, provide a vocabulary for classifying vehicles used to transport goods and people. Within that framework, a commercial truck is defined by its use case: it is a vehicle intended for business activity that involves hauling cargo, rather than personal transit. This classification anchors a broader set of expectations about roadworthiness, durability, and the capacity to operate within legal limits. The line between commercial and private use is not merely academic. It translates into concrete engineering targets and testing protocols, including structural integrity, steerability, braking distances, chassis flexibility, and resilience to the stresses of heavy payloads and long hours on the road. The emphasis is on predictability: fleets need to know that a given vehicle, loaded to a particular weight, will behave within a known envelope of performance and safety, whether it is cruising through a sunlit desert corridor or navigating a snowbound urban interchange.

Turning from definition to design, the truck family can be understood as a menu of configurations tailored to cargo type and route geometry. Flatbed trucks embody openness by design. They carry oversized, irregular, or exceptionally heavy loads that do not fit under a traditional box. The lack of a roof or sidewalls is intentional, enabling loading by crane, forklift, or ramp. This openness, however, is matched by strict rules on securing the load and distributing weight across axles to prevent shifts that could destabilize the vehicle at speed. The open deck is efficient for certain types of work but demands disciplined practice and standardized rigging to ensure safety on public roads. The door to successful operation swings on attention to securement details: the choice of tie-downs, fastening patterns, lashings, and the ongoing discipline of checking the cargo before departure.

The realm of heavy-duty trucks—those built to move 17-ton or 50-ton class payloads—puts a different emphasis on structural robustness and axle geometry. In this space, the configuration of axles becomes a central design and operational issue because it directly determines weight distribution, traction, braking effectiveness, and the range of feasible routes. A forward-control layout places the engine behind the front axle, sometimes under the driver’s seat, yielding a shorter wheelbase and tighter turning radius. This translates to enhanced maneuverability in busy yards or narrow streets, a practical advantage for urban delivery and short-haul work. Yet forward-control models often cap engine size and can compromise long-haul comfort and maintenance access, which can ripple into higher operating costs over time. Conversely, conventional trucks place the engine at the front, offering aerodynamics and ride comfort better suited to long-distance travel. They may present a longer wheelbase and a more accessible maintenance regime, supporting sustained highway performance and driver endurance on multi-day routes. The trade-offs are real: for fleets focused on regional routes with heavy urban segments, a forward-control approach can win out; for those prioritizing efficiency over extended hauls, a conventional arrangement may prove superior. The choice is never abstract; it is a calculated response to route mixes, payload patterns, driver fatigue considerations, and maintenance logistics.

Beyond the chassis and drivetrain, the shape and capacity of the cargo area itself demand careful planning. Box vans, with their enclosed, weather-protected cargo bays, are the workhorses of city logistics and regional distribution. High ceilings—often exceeding ten feet—enable workers to stand and move within the cargo space, accelerating loading and unloading of tall items and improving warehouse-to-vehicle handling efficiency. But height is not free; it introduces practical constraints on road clearance, parking, and vehicle stability. The higher center of gravity associated with taller boxes can alter the dynamics of cornering and trailing loads, demanding meticulous attention to load distribution and securing practices to preserve stability in gusty winds or sudden maneuvers. Drivers and dispatchers must plan routes that respect vertical clearance limits and height-restricted infrastructure, reinforcing the idea that compliance is not a separate phase at the end of procurement but an ongoing discipline embedded in daily routing decisions.

In the more specialized end of the spectrum, vehicles designed for mobile retail or service operations illustrate how commercial trucks adapt to an evolving landscape of business models. These units must balance cargo capacity with electrical power management, brand visibility, and regulatory compliance across industries as varied as food service, medical supply, and on-site maintenance. The electrical backbone matters here: lighting, refrigeration, cooking or heating elements, point-of-sale devices, and communication systems all draw power and demand robust electrical safety and reliability. Regulatory regimes governing food safety, health standards, and hygienic handling become part of the vehicle’s design brief. The objective is not only to transport goods but to present a viable, compliant storefront or service platform that can operate independently of external power grids for defined periods. The engineering challenge is to preserve the integrity of the cargo while satisfying safety codes for electrical systems and ensuring the vehicle does not intrude on the surrounding environment through noise, emissions, or visual impact.

Smaller commercial models also play an essential role, especially for small-to-medium enterprises and rural operators. These vehicles offer a bridge between personal-use trucks and larger fleet machinery, delivering practical advantages in cost and ease of operation while still facing the same regulatory demands as larger units. Emissions controls, fuel efficiency standards, and safety features such as visibility equipment and underride protection are not optional add-ons but core requirements that influence design choices and operating costs. The aim is to maximize the number of delivery cycles per day, reduce fuel consumption per mile, and maintain a robust reserve for peak demand periods—all without compromising safety or legality. The story across these classes is consistent: design choices are pragmatic responses to a cargo mix and a network of routes, all embedded within a framework of rules designed to protect people, property, and the environment.

This leads naturally to the practical world of compliance. Across borders and regions, standards bodies, regulators, and industry organizations translate the physics of mass, inertia, and heat into concrete rules. A central concept in this landscape is the maximum gross vehicle weight, a ceiling that defines the total allowable weight of the vehicle including its cargo. Axle-weight limits, dimensional restrictions such as length, width, and height, and the allowable engine- and exhaust-related emissions levels—these are the parameters fleets monitor continually. The performance of the braking system, steering accuracy, suspension resilience, and lighting are not cosmetic goals; they are measurable criteria under which vehicles are tested and certified before they are cleared for service. The regulatory fabric is deliberately comprehensive because it must address a wide range of risk factors: the integrity of the structure in a collision, the ability to stop safely in a variety of weather, and the comfort and alertness of drivers who bear primary responsibility for safe operation day after day.

Emissions and energy efficiency, in particular, have moved from ancillary considerations to central design drivers in many markets. The environmental footprint of a fleet is not merely a corporate image issue; it shapes vehicle architecture—from engine mapping and torque curves to transmission gear ratios and aerodynamic aids. As regions tighten emissions targets and pursue cleaner urban air, manufacturers and operators alike confront a balancing act: can the truck move the required payload across the assigned route without consuming excessive fuel or emitting pollutants that cities aim to curb? The answer increasingly lies in integrated solutions that blend mechanical design with digital technology. Telematics enable real-time monitoring of fuel economy, load distribution, tire wear, and brake performance. Predictive maintenance reduces downtime and extends the life of critical components. Advanced driver-assistance systems, though once optional, are becoming standard safety features that support safer operation and can influence insurance and liability considerations. All these elements are not independent gadgets but interconnected parts of a system that orders risk, cost, and reliability.

To appreciate the practical consequences for a business, consider how fleet decisions unfold in real life. A manager must assess cargo profiles, route maps, delivery windows, and local regulatory environments. A local-delivery operation may prioritize nimble box vans and short, predictable routes toward a steady rhythm of stops. A regional network might require heavy trucks with rugged suspensions capable of enduring multiple loading cycles across varied terrain and weather. A national or international freight operation has to optimize for long-haul efficiency, reliability, ease of maintenance in multiple jurisdictions, and strict adherence to cross-border rules. In each case, the design of the truck is not just about raw capacity but about how manageable and predictable the vehicle remains under pressure. The same principles apply to safety and compliance: a vehicle that complies with the letter of the law and the spirit of safety will drive better outcomes for everyone involved—drivers, operators, customers, and the public at large.

This is where the art of procurement meets the science of regulation. The decision to acquire a given truck type is a strategic move that aligns with the business’s service promise, customer expectations, and risk tolerance. A fleet may lean toward forward-control designs in dense urban markets to reduce turning trouble and improve yard maneuverability, while a long-haul operator may favor conventional layouts for their comfort and straightforward maintenance and fueling logistics. The cargo profile—the weight, shape, and fragility of the goods—dictates enclosure types and interior configurations. Load securing becomes a language that drivers, dock workers, and dispatchers share, a system of checks and rituals that prevent shifting loads and compromised stability. And as regulatory regimes evolve, fleets adapt through training, updated maintenance protocols, and, when necessary, the procurement of new chassis and powertrains that meet the latest standards while maintaining the capacity to serve the business’s customers.

The story of the commercial truck, ultimately, is not about a single machine but about a continuously evolving relationship among design, use, and rule. Safety is built into the core of the vehicle through structural choices, restraint systems, braking technology, and the geometry of the cab. Environmental goals push toward cleaner powerplants, smarter aerodynamics, and better energy management, while road-use rules enforce a shared sense of responsibility for weight, height, and behavior on public infrastructure. The end result is a fleet that can be counted on to move weight efficiently, respond predictably to changing conditions, and do so with a minimized risk profile for drivers and other road users. The chapter’s throughline is simple but powerful: defining what a commercial truck is requires looking at how it is designed, how it is used, and how it must conform to a web of standards that keeps people safe, cargo intact, and commerce flowing.

For readers who want to explore a facet of this topic beyond the technical contours, the discipline of emissions regulation and its practical implications for truck design offer a revealing lens. The industry is increasingly conscious that standards and policies do not merely constrain manufacturers; they shape the choices fleets make about routes, maintenance intervals, and the timing of fleet modernization. In this sense, the phrase OEMs seek clarity in emissions regulations acts as a mirror for how all players in the system—creators, operators, regulators, and customers—navigate the transition toward cleaner, more efficient freight movements. OEMs seek clarity in emissions regulations is a reminder that the road to better trucks runs through a shared understanding of policy, engineering, and practice.

To ground these reflections in practice, consider the layered nature of corridors that trucks inhabit. Local streets, with their narrow lanes and frequent pedestrian activity, demand handling characteristics that emphasize braking response, steering control, and low-speed maneuverability. Regional corridors test the vehicle’s ability to maintain stability with varying weather and weight combinations while remaining economical in fuel use and durable over many cycles of loading and unloading. International routes confront cross-border rules that layer additional dimensions on top of the usual mechanical and safety requirements. The chain of compliance stretches from the manufacturing plant to the consumer’s doorstep, with ports, warehouses, and distribution centers acting as waypoints where loads are secured, inspected, and reallocated as needed. In this context, the concept of a commercial truck becomes a narrative about adaptation: a vehicle designed not just for a moment of operation but for a long, trackable life in a network that demands reliability and resilience.

In closing this reflection on definition, design, and compliance, the core takeaway is that a commercial truck is not a monolith but a family tailored to a spectrum of cargo needs and operating environments. Its design embodies a careful trade-off between payload capacity, maneuverability, durability, and energy efficiency. Its compliance footprint extends throughout its life—from the moment it is specified and built, through the routine maintenance and inspections that keep it roadworthy, to the ongoing reporting and documentation that attests to its lawful operation. The vehicle thus sits at the intersection of engineering discipline, business strategy, and public policy—a nexus where every load, every kilometre, and every mile of regulatory compliance contribute to a single objective: moving goods safely, efficiently, and responsibly across the vast and varied landscape of modern commerce.

External resource for deeper regulation details: https://www.fmcsa.dot.gov

Final thoughts

Commercial trucks are the backbone of the logistics sector, influencing efficiency and reliability across industries. Understanding their classifications, roles in supply chains, and adherence to design and compliance regulations is crucial for optimizing operations. As logistics and freight company owners, construction and mining procurement teams, and small business owners navigate the complexities of transportation, focusing on these aspects can lead to significant improvements in efficiency, cost management, and overall service quality.