The AM commercial truck industry plays a pivotal role in transporting goods and fulfilling logistics needs across various sectors. For logistics and freight company owners, construction and mining enterprises, and small business owners with delivery fleets, a comprehensive understanding of this industry is essential. This article delves into five key aspects: an overview of the industry, the types of commercial trucks and their applications, the regulatory environment governing these vehicles, recent technological innovations, and current market trends. Each chapter provides insights aimed at enhancing operational efficiency and strategic decision-making, equipping stakeholders to navigate the AM commercial truck landscape effectively.

Shifting Gears in the AM Commercial Truck Industry: Electrification, Regulation, and the New Logistics Reality

The AM commercial truck landscape is not simply evolving; it is being redesigned around the twin pressures of decarbonization and demand for reliability in an increasingly complex logistics world. In the medium- and heavy-duty (MHCV) segment, these vehicles represent a relatively small share of overall on-road sales, yet they command a disproportionate influence on energy use and the flow of goods. In 2023, MHCVs accounted for less than 4% of on-road vehicle sales (excluding three-wheelers), but they carried a far larger share of road transport liquids demand and CO2 emissions. This stark contrast highlights why policymakers, fleet operators, and manufacturers are paying close attention to every decision made in the MHCV space. The chapter that follows in this volume situates AM markets within this larger frame, tracking how regulators, technology developers, and customers converge to redefine what a commercial truck can do, how it is powered, and how it fits into a broader strategy of resilience and sustainability.

A pivotal feature of the current moment is the dual pathway that industry observers call the Inflections and Green Rules scenarios. The Inflections scenario envisions a continuation of current decarbonization trends—progress, but gradual and constrained by cost, infrastructure, and the pace of adoption. The Green Rules scenario, by contrast, imagines a policy-driven acceleration where ambitious regulations catalyze what amounts to a clean-energy revolution in the MHCV sector. The contrast between these paths is more than academic. It informs investment decisions, research priorities, and the way fleets stage transitions from diesel to electrified powertrains or other low-emission architectures. It also frames the design priorities for trucks and their components, where durability, fuel efficiency, and safety are not merely technical concerns but strategic imperatives tied to regulatory timing and market readiness.

From a market perspective, the global commercial vehicle sector is robust, with the broader economy driving demand for efficient, reliable transport. The sector’s value surpassed USD 1.34 trillion in 2025 and is projected to reach USD 2.31 trillion by 2035, a compound annual growth rate of about 5.6%. This expansion reflects the growth of logistics networks, the continuous upgrading of infrastructure, and the increasing sophistication of transportation systems that enable smarter routing, better asset utilization, and tighter operating margins. In AM markets, this environment translates into a push for more intelligent, more capable trucks that can negotiate urban environments as easily as long-haul corridors, while delivering less noise, less vibration, and lower environmental impact. It also means manufacturers and suppliers are working more closely with fleet operators to tailor solutions that balance upfront cost, total cost of ownership, and the critical requirement for uptime.

Technology and regulation intersect in meaningful ways in this transition. Powertrain development is rapidly shifting toward electrification and alternative fuels, not as a single leap but as a sequence of innovations that gradually broaden the feasible mission profiles for MHCVs. Battery capacity, energy density, charging architectures, thermal management, and the integration of advanced power electronics are all areas where incremental progress compounds into real gains in range, efficiency, and reliability. Hybrid configurations, opportunities for hydrogen-based propulsion, and other e-fuels are not mere experimental curiosities; they are part of a diversified strategy to meet diverse duty cycles, from metropolitan delivery routes to regional haul corridors. The pace and composition of this shift are strongly shaped by policy clarity, grid readiness, and the economics of fuel and energy storage, all of which influence the timing of fleet retirements and the calculus of new-vehicle purchases.

Within this broader shift, there is a growing emphasis on safety and operational efficiency as non-negotiable outcomes. As regulatory regimes tighten, vehicle specifications evolve to address crashworthiness, braking performance, and operator ergonomics. At the same time, the industry is embracing digitalization and connectivity as a means to optimize maintenance, scheduling, and driver training. Intelligent transportation systems (ITS) and data-driven fleet management enable more precise asset utilization, reducing unnecessary miles and smoothing demand across networks. This is not a case of replacing one set of problems with another; it is a reallocation of resources toward systems that deliver reliability, safety, and lower emissions over the life cycle of a vehicle.

An important, tangible example of component-level innovation that has broad implications for performance and longevity is the development of rolling sleeve air springs—sometimes referred to as rolling lobe air springs—for front suspensions. This design, with its cylindrical form and flexible internal sleeve, rolls on a piston during extension and retraction, reducing friction and wear while improving lateral stability. Such innovations may seem incremental, but they contribute to lower maintenance costs and improved ride quality, both essential for fleets seeking to maximize uptime and minimize the total cost of ownership in a demanding operating environment. They also illustrate how advances at the component level reinforce broader goals: reducing weight where possible, improving control and safety, and extending the service life of critical subsystems. A comprehensive overview of air bag technologies, including their types and manufacturing applications, provides a helpful context for how these elements fit into the larger product ecosystem.

As the AM market navigates these shifts, it is crucial to connect the regulatory narrative with real-world implications for fleets, manufacturers, and even policymakers who shape the rules of the road. Emissions regulations increasingly influence not only the choice of powertrain but also the design of vehicle and engine architectures, cooling systems, and thermal management strategies. In this climate, industry players seek clarity and predictability from regulators, aiming to align product development roadmaps with policy trajectories. An accessible thread through this conversation is the idea that clarity in emissions regulations helps reduce perceived risk and speeds up the adoption of cleaner technologies. This is not about chasing a single technology; it is about building a portfolio of solutions that can be deployed across a range of duty cycles and operating environments. The reference to regulatory clarity is not a side note but a central determinant of how quickly fleets can move from diesel to alternatives and how swiftly vehicle manufacturers can scale up production and support networks to meet rising demand.

The AM region’s urban and regional logistics require trucks that are nimble enough for city streets and capable enough for longer routes. This duality pushes innovations in chassis design, weight management, and aerodynamics, as well as in energy storage and charging infrastructure. It also underscores the importance of intermodal and cross-border considerations, where efficient, reliable equipment and predictable regulatory environments help keep supply chains flowing. The broader trend toward intelligent, automated, and connected trucking systems means the next generation of AM trucks will be asked to do more with less—higher uptime, lower emissions, and faster, more predictable delivery windows. Those requirements are shaping a future in which the AM segment does not merely adapt to change but helps set the pace for energy transition, safety, and efficiency in the global trucking ecosystem.

To readers who want a concrete link to ongoing policy discussions in the AM space, consider the ongoing dialogue around emissions regulations and how OEMs are seeking clarity in the regulatory path. This dialogue is a reminder that policy design matters as much as engineering prowess in determining which technologies proliferate and where investment lands. The industry’s collective prudence in interpreting and responding to regulatory signals will influence equipment choices, financing decisions, and the pace of deployment across regional markets. As a result, the AM commercial truck sector stands at a crossroads where disciplined adherence to safety standards, coupled with pragmatic adoption of electrification and alternative fuels, can yield a durable competitive advantage for fleets that plan thoughtfully for the long term.

For readers seeking a deeper dive into the regulatory dimension, the conversation around emissions regulations is a critical lens through which to view the AM market’s trajectory. OEMs seek clarity in emissions regulations and a stable planning horizon, which in turn informs the readiness of supply chains, the development of charging and fueling infrastructure, and the pace at which new technologies can reach the marketplace. This alignment between policy clarity and technological readiness is essential for turning decarbonization aspirations into practical, scalable deployment across a wide range of duty cycles and operating environments. As the chapter closes, it is clear that the AM commercial truck industry’s future is not a single path but a coordinated route map: a blend of electrified powertrains, smarter vehicle systems, safer and more durable components, and a regulatory framework that supports speed, safety, and sustainability in equal measure. In this evolving landscape, the industry’s resilience will hinge on its ability to translate policy signals into credible investment plans, and to translate those plans into trucks that move goods efficiently while protecting people and the planet.

External resource: A comprehensive overview of air bag and related component technologies in trucks can be found here for broader context on how these innovations support the overall efficiency and safety of commercial vehicles: https://www.truckairbags.com/commercial-truck-air-bags-overview

Internal link reference: For ongoing policy and regulation discussions that shape industry strategy, see the conversation around emissions rules and the search for regulatory clarity: OEMs seek clarity in emissions regulations.

AM Commercial Trucks: A Practical Guide to Fleet-Proof Vehicles

AM Commercial Trucks sit at the heart of modern logistics, a diverse family of heavy-duty vehicles built to move goods, support construction, and sustain services across geographies. In a family-run dealership with three decades of experience, the catalog becomes a practical ecosystem where fleet operators map specific tasks to vehicle capabilities, balancing upfront costs with long-term reliability and uptime. The lineup spans tractor units for long-haul freight, heavy-duty workhorses for rough job sites, and specialized trucks that address niche challenges. Across this spectrum, the guiding principle remains constant: reliability, fuel efficiency, safety, and easy access to parts and service to keep fleets moving on tight schedules and margins.

Tractor units form the backbone of freight networks, pulling vast quantities of goods across highways and linking manufacturers, distributors, and retailers. They must sustain long miles, diverse climates, and time-critical windows. Fuel efficiency translates into operating costs, while advanced safety features protect drivers and cargo. Comfort and intuitive controls help reduce fatigue on multi-day routes, and flexible product lines support growth without sacrificing uptime.

Beyond highways, heavy-duty trucks tackle demanding environments – construction sites, mining operations, and large-scale material transport. A reinforced chassis, rugged axles, and high-torque powertrains enable these vehicles to haul heavy loads in tough terrain, with durability and serviceability as key metrics for fleet operators.

Specialized transport vehicles add precision to logistics. Container tractors tow standard containers, enabling smooth intermodal moves from ports to rail yards to distribution centers. Tankers demand safe containment of liquids or gases, while reefers preserve the cold chain for perishables. Dump trucks support efficient on-site material handling, keeping worksites tidy and productive. Each specialization reduces risk and expands the markets a fleet can serve.

Industry dynamics are evolving toward smarter operations and sustainability. Electric and hybrid powertrains, telematics, and data analytics enable route optimization, predictive maintenance, and proactive driver coaching. Emissions regulations and safety standards push manufacturers to cleaner propulsion and smarter braking. A diversified AM Commercial Trucks lineup helps fleets balance upfront investment with long-term savings, making it possible to mix new and used equipment to fit routes and budgets.

From the perspective of a family-run dealer, service and aftercare are as vital as the sale itself. A reliable supply of parts and skilled technicians keeps uptime high and maintenance predictable across regions and regulatory environments. The dealer’s role as strategic advisor includes maintenance planning, uptime optimization, and fleet renewal strategies that align vehicle classes with route patterns, seasonal demand, and capacity commitments.

In practice, fleets benefit from selecting the right vehicle for each task rather than repurposing multipurpose units. This approach boosts productivity, reduces risk, and improves customer satisfaction by delivering more predictable deliveries and steadier cash flow. The industry continues to move toward flexible combinations of tractor units, heavy-duty trucks, and specialized vehicles to meet evolving market demands.

Regulatory Crosswinds: Global Rules Shaping Autonomous Commercial Trucks and the Future of Freight

Regulatory expectations for autonomous commercial trucks are no longer a narrow safety checkbox but a strategic framework that steers how, where, and when automated freight can move. Governments around the world are weaving climate ambitions, road-safety improvements, and technology readiness into regulatory fabrics that determine not only vehicle design but the very contours of logistics networks. As emissions-reduction targets tighten and the demand for resilient supply chains grows, regulators seek to align automation with decarbonization goals, ensuring that the push for efficiency does not outpace safety or public trust. The result is a dynamic landscape where policy signals can accelerate the adoption of automated mobility while also constraining it with stringent standards that ensure reliability, interoperability, and environmental responsibility. This chapter follows that signal flow across major regions, revealing how policy choices translate into technical requirements and deployment pathways for autonomous heavy-duty trucking, and why those choices matter to shippers, carriers, and policymakers alike.

In the United States, the regulatory conversation centers on ensuring that automated heavy vehicles can operate with demonstrable safety and predictable performance as they begin to share the road with human-driven trucks and other users. The Department of Transportation and the National Highway Traffic Safety Administration have been actively shaping frameworks that balance ambitious innovation with rigorous oversight. A notable feature of the current trajectory is the development of long-term emissions and fuel-efficiency standards that would apply to medium- and heavy-duty automated trucks as technology matures. These proposed standards are not mere mileage targets; they are performance requirements that integrate with the capabilities of autonomous systems. In practice, the combination of optimized routing, platooning, and energy management afforded by automation has the potential to lower overall fuel consumption and reduce emissions, but achieving that potential requires policy to clearly define how automation is tested, demonstrated, and verified before broad deployment. The regulatory path in the U.S. thus links environmental performance with technology readiness, encouraging manufacturers and operators to invest in systems that deliver verifiable gains in efficiency while maintaining safety and accountability.

Across the Atlantic, Europe has chosen a more integrated approach that pairs road-safety mandates with a strategic push toward zero-emission freight. The General Safety Regulation and the Intelligent Transport Systems Directive establish a baseline of safety features and interoperability requirements that new trucks must meet. From 2024, automatic emergency braking and lane-keeping assist have become more than optional aids; they are progressively embedded as standard expectations. This installation mandates framework creates a scaffold upon which future automation can be layered. Europe’s regulatory stance is not isolated from its environmental agenda. The Fit for 55 package and the evolving Euro VII standards form a coherent ecosystem that aligns automated driving with ambitious decarbonization goals. In this setting, automated trucks are anticipated to thrive alongside zero-emission powertrains, amplifying the savings from efficient routing and precise heavy-vehicle control while pushing industry toward electrified or hydrogen-powered propulsion. The harmonization between safety, automation, and clean energy signals a future in which regulatory policies actively shape not only how trucks drive but how they are charged, maintained, and integrated into green corridors across borders.

In China, policy-makers have embraced a comprehensive blueprint that weaves automation into a broader strategy for smarter and cleaner transport. The 14th Five-Year Plan foregrounds intelligent and green transportation as a national priority, with explicit targets to deploy connected and automated freight in key corridors. Local pilot zones in places like Shenzhen and Shanghai function as controlled experimentation grounds where regulatory sandboxes enable real-world testing under tailored rules. The coordination between automation and electrification is central here; national push incentives for electric trucks dovetail with policy support for connected vehicle tech and automated operation. This creates a fertile environment for rapid iteration and scaling, where regulatory allowances encourage pilots that can accelerate learning about how autonomous freight behaves under diverse conditions—from dense urban freight lanes to high-speed express corridors. The Chinese approach demonstrates how a combined focus on automation, electrification, and data governance can compress the learning curve for large-scale deployment while maintaining a stable regulatory pathway for industry players.

Japan’s regulatory evolution is characterized by a steady, deliberate push to enable Level 3 and higher automation on public roads through targeted legal amendments. The Ministry of Land, Infrastructure, Transport and Tourism has prioritized pilot programs for automated truck platooning on highways as a practical step toward improving logistics efficiency and addressing labor shortages in the sector. A central aspect of Japan’s approach is balancing innovation with robust safety frameworks, ensuring that the road-legal deployment of automated trucks is accompanied by clear operational boundaries and oversight. This emphasis on governance, coupled with carbon neutrality goals for 2050, positions Japan as a testbed for advanced automation strategies that can later be scaled in other markets. By prioritizing legal clarity and risk management, Japan aims to demonstrate that automated heavy-duty trucking can be both economically advantageous and socially responsible.

What ties these regional narratives together are three interdependent forces: climate policy, safety mandates, and technological readiness. Climate policy creates the ambition—reducing emissions and transitioning to cleaner powertrains—while safety mandates establish the minimum standard for vehicle behavior and system reliability. Technological readiness provides the practical bridge between policy and deployment, detailing what autonomous systems must demonstrate to satisfy regulators and operators alike. When these forces align, the regulatory environment can catalyze rapid improvements in efficiency and resilience across the freight sector. But misalignment or fragmentation among regions can slow progress. Without timely, harmonized standards, fleets face a maze of test protocols, validation criteria, and cross-border compliance challenges that increase cost and complexity and threaten the promised gains in safety and emissions reductions. In that sense, the regulatory agenda is a central lever for industry strategy, shaping everything from sensor suites and software architectures to data-sharing protocols and cross-border data governance.

Industry observers highlight the practical implications of these policy trajectories for fleet operators and supply chains. For carriers, regulatory clarity translates into predictable capital planning and maintenance schedules. Operators can more confidently invest in platforms that optimize routing, anticipate weather disruptions, and coordinate platooning when the rules governing automation, cybersecurity, and data privacy are well defined. For policy-makers, the challenge is to design standards that are rigorous enough to deliver real safety and environmental benefits, yet flexible enough to accommodate innovations that may arrive faster than anticipated. The trade-off between stringent performance benchmarks and adaptable regulatory pathways becomes a central theme as countries experiment with different paces and combinations of mandating advanced driver-assistance systems and allowing higher levels of autonomy under controlled conditions. Within this tension lies an opportunity to create a unified vision for automated freight that respects national contexts while enabling cross-border collaboration and mutual recognition of safety assessments, testing methods, and interoperability criteria.

Among industry participants, a frequent focal point is how emissions and automation intersect in regulation. The drive to reduce greenhouse gases through cleaner powertrains aligns with automation-driven gains in efficiency, yet this dual objective requires careful policy design to ensure that automated trucks can be evaluated on both safety performance and environmental outcomes. In some cases, this has prompted regulators to link regulatory milestones to demonstrable improvements in energy efficiency or to the deployment of specific technologies, such as platooning or predictive maintenance, that contribute to lower emissions. In parallel, the questions surrounding data collection, sharing, and privacy are beginning to acquire regulatory gravity, given that autonomous systems rely on vast streams of sensor data, vehicle-to-vehicle communication, and cloud-based analytics. Regulatory frameworks are gradually addressing these concerns, aiming to foster innovation while safeguarding consumer privacy and national security.

The broader literature and industry forecasts emphasize a shared understanding: progress in autonomous trucking will accelerate when policy certainty and market incentives reinforce each other. The International Energy Agency’s Road to Transformation report, cited in global policy discussions, underscores how climate goals and technology readiness must align to realize the full potential of zero-emission, automated freight. In practice, this means policymakers will continue refining safety standards, performance metrics, and testing regimes; industry will respond with investment in sensor technology, software reliability, and maintenance ecosystems; and cross-border trade will benefit from more consistent expectations about what constitutes an acceptable level of automation on major freight corridors. For stakeholders seeking a perspective on how regulatory signals translate into practical action, a useful lens is the ongoing dialogue around emissions regulations and how industry best practices can inform policy refinement. OEMs seek clarity in emissions regulations serves as a reminder that industry needs predictable, evidence-based rules to convert policy ambition into tangible, on-road benefits.

As the regulatory tapestry continues to evolve, the next chapters will explore how these rules influence the design decisions behind automation platforms, the integration of electrified powertrains with automated control, and the ways in which infrastructure and workforce training programs adapt to a smarter, greener freight network. The path forward will likely require ongoing collaboration among regulators, manufacturers, carriers, and urban planners to ensure that the era of autonomous commercial trucking delivers safer roads, lower emissions, and more resilient supply chains. External resource for further context on how these shifts fit into a global climate and technology landscape can be found in the International Energy Agency’s Road to Transformation report: https://www.iea.org/reports/road-to-transformation

Redefining the Road: Adaptive Powertrains, Lightweight Materials, and Digital Manufacturing in AM Commercial Trucks

The landscape of AM commercial trucks is shifting from straightforward propulsion and burden-bearing frames toward an integrated system approach that treats power, structure, and sensing as a single, responsive ecosystem. The core drivers of this shift are not isolated innovations but a convergence of adaptive powertrains, lightweight materials, and sophisticated manufacturing and operational intelligence. Together, they promise not only lower operating costs and tighter emissions, but a fundamental change in how fleets are managed, how cargo is moved, and how road performance is understood. In this evolving environment, a truck is less a static machine and more a dynamic platform that reads terrain, load, climate, and driver behavior, then tunes itself in real time to meet the moment. The result is a vehicle that can stretch mileage on long hauls, improve payload efficiency, and respond to urban constraints with a gentler footprint on the highway and the planet.

At the heart of this transformation are adaptive powertrains. These systems continuously balance engine output, transmission parameters, and auxiliary power usage to align with real-time demands. When a truck faces a rising grade or a crowded corridor, the powertrain responds by selecting the most efficient gearing, modulating torque delivery, and optimizing energy flow through the drivetrain. In practice, this means less unnecessary fuel burn during starts, stops, and idling, and a more efficient distribution of energy during acceleration and cruise. The operational benefits extend beyond fuel savings: smoother power delivery reduces wear on components, minimizes sudden throttle transients that can impact tire grip, and lowers peak emissions. For fleet operators, the payoff is amplified by predictive energy management. With every kilometer, the system learns the typical weight combinations, road profiles, and seasonal temperature effects, progressively tuning its strategies to minimize consumption while preserving response and reliability. The narrative here is not about a single gadget but about an energy management concept that can be embedded across diverse truck classes—from long-haul freighters to urban delivery platforms—without sacrificing performance or safety.

Lightweight materials play a complementary, equally decisive role. Every gram shed from the chassis, body, and critical structural components translates into more payload capacity or longer range, depending on the mission. Modern trucks increasingly incorporate advanced composites, aluminum alloys, and high-tensile steels in noncritical zones and load paths to maintain strength and crashworthiness while reducing mass. The implications are broad. Reduced weight lessens rolling resistance, which in turn lowers fuel use for a given load. It also means greater reserve margin for peak operational demands, such as hot-weather climbs or rapid accelerations when overtaking on busy corridors. Yet material choice goes beyond the scale of weight. Effective thermal management becomes easier when the structure itself assists heat dissipation through lighter, more thermally conductive substrates. Safer crash behavior can be achieved with energy-absorbing designs and smarter reinforcement layouts, which protect both the driver and cargo under extreme events. These gains are not ceremonial; they translate into tangible economics for fleets that must balance capital expenditure with life-cycle costs, maintenance cycles, and downtime risk.

A third pillar shaping modern AM trucks is the fusion of manufacturing and operational innovations. The production line no longer ends at assembly; it continues through the vehicle’s life. Automated welding, robotic assembly, and digital twin technologies enable precise construction and ongoing performance monitoring after deployment. Digital twins—virtual replicas of physical assets—allow engineers to simulate wear patterns, predict component fatigue, and optimize maintenance schedules before parts fail. For fleets, this translates into predictive maintenance that minimizes unscheduled downtime and extends service life. Sensors and telematics networks embedded throughout the vehicle capture diverse data streams: engine health metrics, tire pressures, brake wear, temperature profiles, and even driver behavior patterns. When interpreted by advanced analytics, these data unlock opportunities for safer driving, smoother operation, and better route planning. The value lies not simply in data collection but in the ability to translate data into actionable decisions that improve reliability and reduce total cost of ownership.

The conversation about these innovations would be incomplete without acknowledging the broader ecosystem in which they exist. Regulatory frameworks and market expectations increasingly reward efficiency and greener performance, while also demanding higher safety and resilience standards. It is precisely at this intersection—between material science, powertrain engineering, and digital operations—that AM trucks reach their potential. The adaptive powertrain concept aligns with energy policies pushing for lower emissions without compromising freight reliability. Lightweight materials respond to safety codes that require crashworthiness and durability under a wide range of operating conditions. Digital manufacturing and telematics meet the modern appetite for transparency, traceability, and continuous improvement. In this sense, technology becomes a governance tool as much as a mechanical one, guiding decisions about maintenance intervals, spare parts logistics, and capital investments.

To illustrate how these ideas cohere in the real world, consider the way a modern freight task is executed. A vehicle on a cross-country run negotiates a sequence of terrains, climates, and cargo types. The adaptive powertrain reads the load, the gradient, and the road grade, then determines the optimal energy path while maintaining a consistent drive feel for the operator. Lightweight construction reduces the fatigue impact of long hours behind the wheel and frees up capacity for heavier payloads when needed. Sensors monitor tire health, brake status, and thermal conditions across the drivetrain, feeding data into a fleet-wide dashboard that highlights maintenance priorities and potential efficiency gains. The digital thread connecting design, manufacturing, and day-to-day operation ensures that components are not treated as discrete parts but as interdependent elements of a living system. This is the essence of modern AM truck technology: a harmonized approach where materials, power management, and intelligence reinforce one another to deliver safer, more economical, and more sustainable transportation.

Another layer of sophistication comes from how these trucks integrate with the broader logistics network. As delivery windows tighten and urban corridors become more congested, the ability to adapt on the fly becomes a competitive differentiator. Adaptive powertrains can curb emissions in city centers by modulating idle and cruise operations during slow-moving urban tempo while still delivering the same throughput when the road clears. Lightweight frames enable tighter payload-to-volume ratios, which improves load factor and reduces the number of trips needed to move a given amount of goods. Meanwhile, digital twins and predictive maintenance keep the vehicle ready for the next assignment by minimizing surprises that disrupt schedules. In essence, the technology is not just about engineering novelty; it is about enabling a more resilient, responsive, and economical freight system that can weather fluctuations in demand, fuel prices, and regulatory environments.

The practical implications for operators extend beyond the engineering lab. Fleet managers gain a clearer picture of where savings come from and how to sustain them over time. The cost of ownership improves as vehicles spend more time in service and less time in workshop bays. Downtime is managed through smarter maintenance triggers and remote diagnostics, reducing the financial penalties of missed deliveries. Operator training also evolves, shifting from a focus on handling a single vehicle to understanding an intelligent platform that optimizes energy, safety, and performance across a diverse set of routes and conditions. This integrated view invites a new kind of collaboration among engineers, fleet managers, and drivers—one where insights flow freely, decisions are data-driven, and the vehicle becomes a partner in achieving business objectives rather than merely a tool for moving goods.

Industry discussions and regulatory dialogues increasingly recognize the value of this integrated approach. The shift toward adaptive energy management, lightweight design, and digital continuity demands a more nuanced perspective on how we measure safety, reliability, and environmental impact. Policymakers and standards bodies are paying closer attention to how these technologies interact with charging infrastructures, maintenance regimes, and supply chains for high-strength materials. The evolution also raises questions about workforce readiness, training pipelines, and the role of data governance in an industry that generates massive volumes of operational intelligence. In this context, meaningful progress requires not only technical prowess but a willingness to align incentives, share best practices, and invest in capabilities that sustain performance over the vehicle’s entire lifecycle.

For readers seeking deeper context on the energy-management and adaptive-powertrain themes, industry forums and regulatory forums often host focused conversations that shape the path forward. One such resource highlights the practical implications of cross-border regulatory considerations for advancing these technologies: TCAs cross-border regulatory issues event. This perspective helps connect the technical possibilities with the policy and logistical realities that fleets must navigate as they adopt new engineering paradigms. While the details of each regulatory landscape differ, the overarching lesson is clear: the most effective breakthroughs arise when technology, safety, and commerce are coordinated across the entire transportation ecosystem.

The horizon for AM commercial trucks is not a single invention but a continuum of improvements that reinforce one another. Lightweight materials free capacity and reduce energy sink, adaptive powertrains extract more value from every joule, and digital manufacturing ensures this value is realized consistently across millions of miles of operation. The result is a fleet that moves goods more efficiently, safely, and with a lighter environmental footprint. The chapter thus points to a shared future in which the line between machine and system blurs, enabling more precise control, smarter maintenance, and a more resilient logistics backbone. As these technologies mature, the industry will likely see new business models emerge—models that reward performance, reliability, and sustainability in equal measure—and a broader adoption curve that brings these benefits from pilot programs into routine operations.

External resource for further reading: Adaptive Powertrain Systems in Heavy-Duty Trucks: A Review of Current Technologies and Future Trends. https://www.sciencedirect.com/science/article/pii/S036054462301798X

Riding the Updraft: Market Momentum, Energy Transitions, and Economic Impact in AM Commercial Trucks

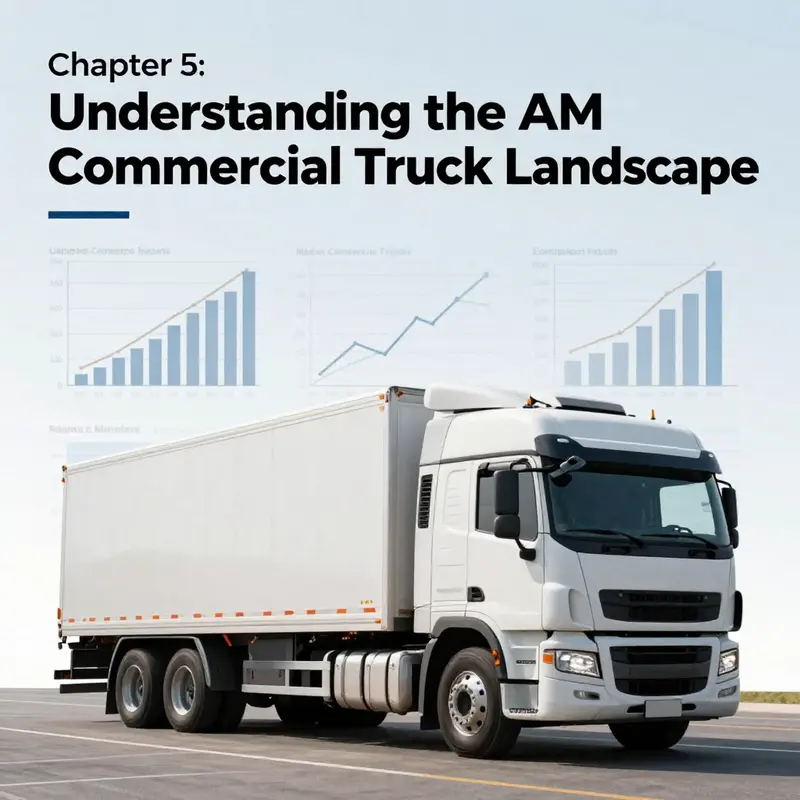

Data coming from September 2025 paints a picture of a market gaining altitude. Production and sales of commercial vehicles reached 3.091 million and 3.117 million units from January through September, marking year-on-year gains of 9.4 percent and 7.8 percent. The lift is broad, but the brightest light shines in new energy commercial vehicles, where demand and product availability are aligning to accelerate fleet decarbonization and compliance with evolving regulations. Natural gas powered vehicles also posted resilience, with 181,000 units sold in the period, up 2.2 percent year over year, underscoring fleets’ willingness to diversify fuel strategies as a hedge against energy price fluctuations and to meet cleaner air targets. In the truck segment alone, September deliveries jumped to 312,000 units, rising 14.9 percent month over month and 28.9 percent year over year. Heavy trucks led the wave with 106,000 units, a stunning 82.9 percent year-on-year increase. Light trucks reached 161,000 units, up a modest 2.5 percent year over year, while mini trucks surged 82.4 percent to 34,000 units. Looking at the nine-month totals, heavy trucks totaled 823,000 units, up 20.5 percent, and light trucks hit 1.482 million, up 6.2 percent. Medium and mini trucks, by contrast, slipped by about 10 percent in the period, signaling some market adjustment after a faster late-2024 rebound and perhaps a shift in fleet replacement cycles or urban delivery strategies. Together these figures tell a story of a logistics and service economy that is rebuilding capacity and reconfiguring its fuel mix. The heaviness of the September surge in heavy trucks hints at intensified activity in sectors like freight transport, construction, and large-scale logistics projects that demand durable, high-availability equipment. When fleets order more heavy units, it often reflects longer freight lanes, higher utilization of vehicles, and a push to modernize with models that promise better uptime and lower per-mile operating costs. The parallel rise in light and mini trucks mirrors last-mile and urban delivery pressures, where nimble, lower-cost platforms help maintain service levels in congested markets and support on-demand inventory systems. New energy and alternative-fuel options have become not just a compliance feature but a core driver of fleet strategy. The sector’s faster adoption of electric, hybrid, and natural gas platforms signals a shift in what fleets demand from manufacturers and what suppliers must deliver. A stable but growing share of sales in natural gas vehicles demonstrates that the market values infrastructure-compatible solutions, even as battery-electric options gain traction in line-haul and urban delivery segments. The 181,000 natural gas units through September show a commitment to cleaner combustion cycles and, crucially, a different planning horizon for maintenance, fueling, and warranties. These shifts ripple through the manufacturing ecosystem, accelerating demand for lighter, safer, more modular powertrains and for services that can support rapid turnarounds in depot and service networks. Behind the numbers lies a broader economic dynamic: automated manufacturing capabilities, improved supply chain visibility, and a greater willingness to invest in green technologies. The truck industry sits at the intersection of equipment-intensive capital spending and the pressure to reduce total cost of ownership. In practice, that means plants upgrading welding, stamping, and assembly lines to accommodate heavier frames for long-haul use while integrating battery pack assembly, thermal management, propulsion control systems, and software platforms that orchestrate fleet operations. The result is a virtuous circle: as production lines become more adaptable to mixed-energy platforms, fleets gain access to standardized components that simplify service and parts logistics, lowering downtime and extending vehicle life. Policy and market signals reinforce this dynamic. Regulators push for cleaner emissions and safer operation, while fleet operators balance upfront capital with operating expenses and residual values. The link between policy clarity and supplier performance grows stronger every year. For manufacturers, even a modest delay in regulatory clarity can ripple through product roadmaps and cash flows; hence, the frequent industry chorus around emissions regulation clarity, spotlighted by the article’s linked discussion OEMs seek clarity in emissions regulations. The nine-month performance implies robust business confidence and a readiness to scale. The logistics chain remains a key engine of GDP, and the expansion in heavy trucks points to sustained investment in infrastructure, warehousing, and cross-border commerce. The interplay between heavy-duty demand and urban delivery needs also highlights the importance of efficiency gains in fuel economy, predictive maintenance, and tire and brake durability. In practice, fleets are increasingly turning to telematics, remote diagnostics, and service networks that promise to minimize downtime and maximize miles logged per unit of capital. This trend toward data-enabled operations is not merely a tech fad; it is a strategic response to volatile energy prices, driver shortages, and the need to extract more value from every asset in a highly competitive market. Beyond vehicle ownership, the rise in sales underpins a broader ecosystem. Maintenance and repair networks expand, independent operators and OEM-approved service centers hire technicians, and aftermarket parts markets grow to support increased vehicle IDs and uptime. Fleet owners demand standardized diagnostics tools to simplify multi-brand support and to reduce downtime during peak seasons. In response, regional suppliers invest in warehousing capacity and training programs to ensure rapid availability of critical components, creating a multiplier effect on employment and regional income. The capex cycle in truck manufacturing, spare parts, and service is closely tied to the overall performance of construction and manufacturing activity, which in turn feeds back into consumer spending, housing, and the broader cycle of infrastructure renewal. Viewed through a broader lens, the momentum described here fits a global narrative of rebound and reconfiguration. Manufacturing activity is strengthening in many regions, trade flows are stabilizing, and the drive to cleaner propulsion is crossing borders at speed. The supply chain story, once haunted by disruptions, now leans toward resilience: more modular supply arrangements, diversified sourcing for critical components, and closer alignment between vehicle design and regional energy grids. The result is a healthier ecosystem where manufacturers, fleets, and service providers share risk and reward more evenly, while workers gain access to skilled roles across plant floors, service centers, and maintenance hubs. For policymakers and industry leaders, the implications extend beyond quarterly results. The heavy truck cycle acts as a bellwether for capital investment in roads, bridges, and logistics infrastructure. It also signals the pace at which fleets will transition to cleaner energy and more automated, centralized maintenance practices. The demand for robust training and workforce development grows in step with the need for technicians who can install, service, and adapt advanced propulsion systems, battery packs, and integrated software. As AM approaches deepen, the capacity to retool factories for multi-energy platforms and to re-skill technicians becomes a competitive differentiator, not a peripheral advantage. The ability to shift production lines quickly to meet regional demand is increasingly tied to the same digital tools that optimize routing and fleet utilization, illustrating how automation and energy strategy converge to shape the industry’s future. For a broader, global context and longer-term revenue projections, industry observers look to comprehensive market analyses that map regional dynamics, regulatory landscapes, and technology adoption. See the external resource for a global perspective: https://www.marketsandmarkets.com/Market-Reports/commercial-trucks-market-1543.html.

Final thoughts

The AM commercial truck industry significantly contributes to the global supply chain, with various truck types serving distinct operational needs. As technology evolves and regulations tighten, understanding these dynamics will empower businesses to maximize their fleet’s potential, enhance compliance, and adapt to market changes. Successful navigation of this landscape requires not only awareness of current practices but also an engagement with emerging trends shaping the future of transportation.