For logistics, construction, and small delivery businesses, understanding the array of gauges in modern commercial diesel trucks is crucial. These instruments not only secure the engine’s performance and longevity but also ensure operational efficiency and regulatory compliance. This article delves into the essential gauges typically found in diesel trucks, including the oil pressure, coolant temperature, exhaust gas temperature, and more. The first chapter offers an overview of common gauges, followed by an in-depth exploration of the functionality of exhaust gas temperature gauges—critical in avoiding engine damage. Lastly, we will detail the significance of oil pressure and coolant temperature gauges, tying together their roles in safeguarding engine integrity.

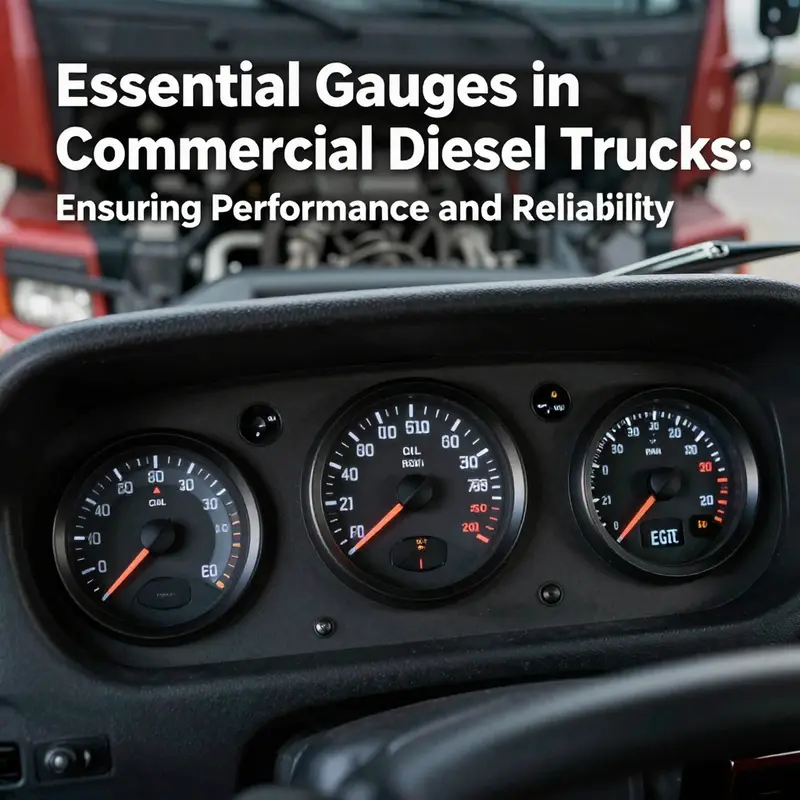

The Fleet’s Vital Signs: Reading the Gauges That Drive Commercial Diesel Trucks

The gauges mounted in a commercial diesel truck are more than simple dials or digital readouts. They are the fleet’s heartbeat, a constant stream of real-time data that translates raw mechanical behavior into actionable insight. For drivers on the road and fleet managers watching a dashboard from a regional office, those numbers, lines, and lights tell a story of health, safety, and efficiency. They reveal everything from the quiet, steady march of an engine that’s well lubricated to the momentary tremor that warns of a cooling system’s strain. In this sense, gauges are not just instruments; they are the custodians of reliability. They interpret the machine’s internal world for the human who operates it, translating cylinders’ rhythm and pistons’ sighs into a language that can be read, understood, and acted upon across hundreds of miles of highway and thousands of hours of service.

The most fundamental set of this language centers on the engine itself. The engine oil pressure gauge, for instance, is a steward of lubrication. Oil circulates to dampen metal-on-metal contact, carry away heat, and carry away contaminants. When pressure falls, it signals trouble whether from insufficient oil, a failing pump, a block or leak, or an overzealous demand from worn bearings. Conversely, excessively high pressure can indicate a blockage or a faulty sensor that misreads the system. Either extreme can lead to accelerated wear or premature failure if the driver continues to operate without investigation. A healthy oil pressure reading, in contrast, reassures the operator that the engine’s lifeblood is circulating properly, a quiet promise of reliability even as the truck works long hours and harsh conditions.

Beyond lubrication, the coolant temperature gauge is another core metric. Diesel engines generate heat, and the cooling loop acts as a steady regulator that keeps combustion and friction from tipping into dangerous territory. The gauge’s needle or digital readout anchors the driver’s sense of thermal balance. Early signs of cooling system distress—rising temperatures, fans that rev aggressively, or a thermostat that won’t settle—become obvious on screen long before the engine reaches a critical limit. An overheating event is not merely an issue of comfort; it presents a direct threat to gasket integrity, head studs, and the long, patient work of the pistons and liners. The gauge thus becomes a sentinel, inviting a driver to slow, monitor, and seek a safe solution before the day’s schedule is derailed.

Fuel level gauges, while seemingly simple, are equally practical in the long-haul environment. They shape the network of refueling stops that fleets plan to minimize downtime and maximize uptime. In remote corridors where a fill-up is not just a matter of convenience but of logistics, an accurate fuel gauge helps prevent stranded miles from the next station. These instruments feed into route planning and budgeting, because a fuel shortfall is both a risk to operations and a cost that compounds when delays occur or when a vehicle idles in search of fuel. In this light, fuel level is not a trivial metric. It is a determinant in the choreography of a day’s drive, influencing schedules, maintenance windows, and even driver fatigue management when the landscape imposes long stretches without services.

Electrical health completes the quartet of core metrics that most fleets monitor with equal seriousness. The battery voltage or alternator gauge tracks the state of charge in a system that must stay alive to start the truck, power the lights, and run the radios and telematics that connect the vehicle to the fleet’s management network. A fluctuating voltage, a sagging battery, or an alternator that can’t keep pace with demand signals a potential failure in the making. In heavy-duty service, a surprising number of no-start incidents trace back to a charging circuit problem. The gauge, therefore, does more than reflect current flow; it acts as a preemptive alert, inviting maintenance action before a roadside interruption becomes a costly delay.

For many diesel engines, the turbocharger introduces another layer of information that the driver can observe through a boost gauge. Turbocharged engines rely on precise control of intake pressure to achieve efficiency and power, particularly when the truck faces hills, heavy loads, or adverse weather. The boost gauge helps the operator recognize when the turbo is underperforming, whistling through leaks or suffering from worn bearings, or when the engine is pulling air faster than the exhaust can exhaust, a mismatch that often hints at a larger intake or exhaust constraint. The driver can then adjust throttle behavior or report the anomaly for maintenance, preventing a decline in performance that could ripple into higher fuel consumption, reduced power, and increased engine smoke.

Another gauge that occupies a special place in the diesel engine’s diagnostic toolkit is the exhaust gas temperature gauge. Exhaust gas temperature, or EGT, is a measure that connects combustion efficiency with exhaust flow and aftertreatment behavior. It is especially valuable in high-load situations where the engine is pushed toward its limits, such as climbing steep grades or sustaining heavy acceleration. Elevated EGT readings can indicate problems like over-fueling, restricted exhaust flow, or a misfire that allows raw fuel to burn in the exhaust system instead of inside the cylinders. Prolonged high EGT not only degrades fuel economy but also accelerates wear on the turbine, the oxygen sensors, and the catalytic aftertreatment system. The EGT gauge, therefore, acts as a sentinel for both performance and emissions integrity, reminding the operator that efficiency and compliance are intertwined in the engine’s daily life.

In many heavy-duty applications, the basic cockpit ensemble expands to include specialized gauges that monitor auxiliary systems essential to mission-critical reliability. Transmission temperature gauges reveal how the drivetrain is handling shifting and torque transfer, especially in heavy-laden operations where heat can accumulate as gears mesh and oil flows meet high demands. Differential temperature gauges provide insight into axle and lubrication health, useful in applications where load distribution can place unusual stress on axles. These readings are not showpieces; they become practical signals that the truck should be observed more closely, serviced, or re-routed to avoid accelerated wear or unexpected failures. The collection of gauges thus forms a broader map of the vehicle’s mechanical ecosystem, where each measurement informs a different facet of risk and opportunity.

Across this landscape of gauges, the human factor remains central. The best dashboards are designed to align with how drivers read and respond to information in the cab. Colors, alarms, and response thresholds shape behavior. A red alert for oil pressure, for example, invites immediate action. A yellow caution for a rising engine temperature might signal the need for a more conservative driving style or a stop for a check before the situation deteriorates. The driver’s ability to interpret these cues quickly is a critical link in the chain of safety and uptime. Yet gauges do not operate in isolation; they feed into the broader ecosystem of fleet management where data is aggregated, historical trends are analyzed, and maintenance cycles are scheduled around real patterns rather than reactive fixes.

Digital dashboards and telematics platforms increasingly synthesize gauge data into actionable dashboards. They translate discrete gauge readings into trends, alert histories, and maintenance forecasts. Fleet managers can see which vehicles are trending toward critical thresholds, identify recurring issues across a region, and optimize maintenance windows to minimize downtime. This data-driven approach does not replace the driver’s expertise; it augments it. The gauge remains the real-time interface, while the platform provides context, correlations, and forward-looking insights. In this synergy, gauges contribute to a culture of proactive maintenance, where preventive work reduces the probability of accidents, roadside failures, and expensive repairs.

One practical dimension of this landscape is the balance between analog gauges and digital instrumentation. Some operators still prefer the immediate, tactile reassurance of a traditional needle gauge, where a glance and a glance only offers a sense of the engine’s status. Others lean into digital displays that aggregate dozens of metrics into a single screen, offering more nuanced cues about health, efficiency, and compliance. The choice is not merely stylistic; it influences how quickly a driver can react, how easy it is to notice subtle deviations, and how well the vehicle integrates with a fleet’s broader data architecture. Regardless of format, the goal remains the same: to provide a fast, accurate, and unambiguous read on conditions that matter for performance, safety, and longevity.

The role of gauges also intersects with the realities of maintenance programs and regulatory expectations. In fleets where uptime is mission-critical, a loom of gauges becomes a risk map: any deviation triggers a chain of checks, tests, and interventions designed to keep the vehicle in service and within environmental rules. This is particularly relevant when considering emissions regulations and the reporting of engine behavior under load. The readings from EGTs, boost levels, and temperatures can reflect how the engine manages combustion and exhaust treatment under real-world conditions. When gauges indicate stress, technicians adjust schedules, calibrate controls, or verify the integrity of sensors and piping that connect the engine to its aftertreatment system. In these contexts, gauge data is not merely diagnostic; it is a practical conduit for compliance, efficiency, and safety.

The everyday patterns of use illuminate why gauges remain indispensable even as software and connectivity evolve. A driver on a long haul might experience variations in ambient temperature, altitude, and driving style, yet the gauges normalize these fluctuations by presenting a coherent picture of the engine’s health. A small uptick in coolant temperature or a drop in oil pressure, observed over minutes rather than seconds, can signal a trend that warrants a sanctioned stop for inspection. In contrast, the same gauge movements during a city route may carry different implications because the duty cycle, engine load, and air flow interact with the gauge’s baseline in a distinct way. The same instrument can thus tell a different story depending on context, and interpreting that story requires the driver to be trained, attentive, and empowered to act when necessary.

This human-technical interface—driver interpretation, gauge design, and fleet analytics—also reflects broader industry conversations about how gauges support safety, reliability, and regulatory compliance. For instance, industry dialogues often frame the issue around how these gauges intersect with regulatory expectations, as seen in discussions labeled OEMs seek clarity in emissions regulations. The idea is not that gauges alone determine compliance, but that the data they surface informs when and how emissions systems are engaged and monitored under real-world conditions. When a driver notices unusual EGT readings during a climb, the appropriate response may be to moderate throttle, adjust to a safer speed, or schedule a maintenance check that verifies exhaust pathways and the integrity of catalytic and particulate components. In this way, gauges contribute to both performance and accountability, helping operators stay within the lines drawn by regulators while also protecting the machine and the crew.

As we consider the broader implications, it’s worth acknowledging that the gauge ecosystem is evolving without erasing its practical core. The move toward more integrated, data-rich dashboards does not remove the need for reliable, interpretable readings. If anything, it heightens the expectation that readings are timely, accurate, and actionable. A gauge reading that arrives too late or that is difficult to interpret loses relevance. This is why calibration, sensor health, and software reliability are central to the gauge’s value proposition. It is also why the human element—the training, the situational awareness, and the disciplined response to alerts—must keep pace with technological enhancements. In the long run, the gauge is not a final authority but a trusted interface that connects the driver, the technician, and the fleet’s strategic objectives.

The chapter of the vehicle’s life that gauges illuminate is not just about avoiding breakdowns; it is about enabling consistent, predictable performance. When a truck runs with well-calibrated, accurately read, and promptly responded-to gauges, the fleet gains not only uptime but also insight into how to optimize routes, loads, and maintenance windows. This translates into better fuel efficiency, lower maintenance costs, and improved safety for drivers and other road users. It is an ecosystem where each gauge contributes a thread to a fabric of reliability that holds together the day’s work, no matter the distance or the demand. The gauges, after all, are the quiet custodians of the vehicle’s health, translating mechanical complexity into human-readable cues that guide decisions on the move.

The conversation around these gauges is not static. It evolves as new engine technologies, fuel formulations, and aftertreatment solutions appear, demanding continuous calibration of what a gauge reads and how drivers should respond. As the industry shifts toward smarter engines, more robust telematics, and enhanced diagnostics, gauges will still occupy the same fundamental role: to present an immediate, intelligible picture of how the truck is performing in real time. The promise is not that gauges will disappear into the background but that their readings will be enriched with context—so a driver’s reflexive action becomes a precise, data-informed decision. In that sense, the gauges’ value endures: they remain the bridge between complex mechanical systems and the human responsibility that keeps fleets safe, productive, and compliant on the road every day.

External resource: https://www.bentley.com/en/insights/articles/diesel-truck-gauges-explained

null

null

Guardians of the Long Haul: The Vital Role of Oil Pressure and Coolant Temperature Gauges in Commercial Diesel Trucks

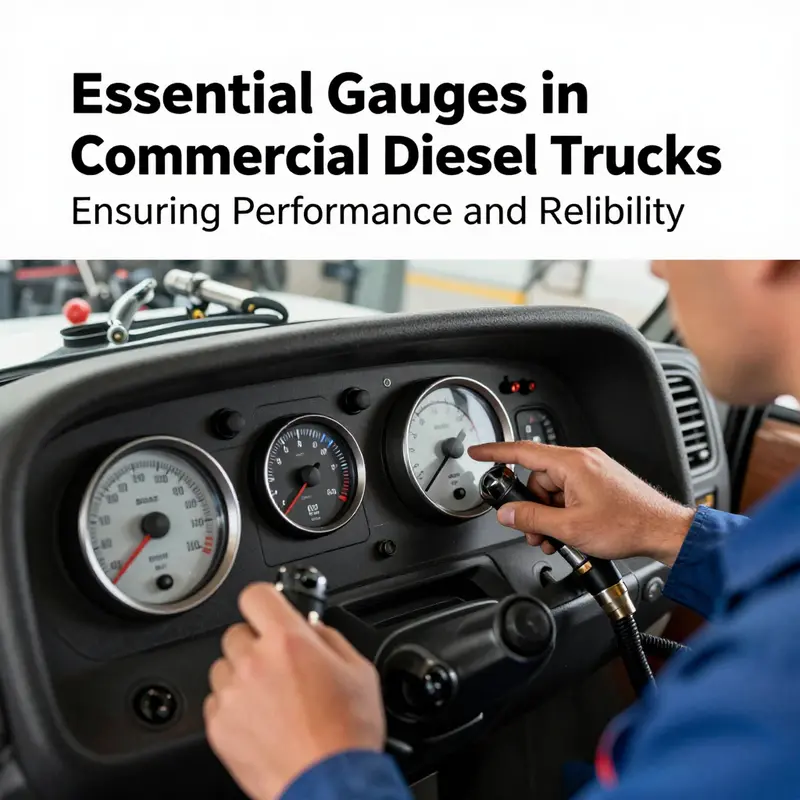

Gauges in a commercial diesel truck are more than dashboard ornament; they are early warning systems that translate complex engine behavior into clear signals a driver can act on. Among the most fundamental of these signals are the oil pressure gauge and the coolant temperature gauge. Together, they form a practical duo that guards the engine’s life and the vehicle’s reliability on long hauls, in urban deliverables, and across the rough terrain where uptime is as valuable as payload. When you look beyond tachometers and speedo needles, these two gauges perform a quiet but essential service: they keep the engine’s heart lubricated and its cooling system disciplined, ensuring the machine remains within its designed operating window even under stress. This is not merely about keeping an engine running; it is about preserving the balance between performance, efficiency, and safety that fleets rely on every day. In this sense, the oil pressure and coolant temperature gauges are the most reliable barometers of the engine’s immediate health, and their readings shape decisions that prevent misfortune on the road and at the dock alike. They are part of a broader philosophy in diesel technology: monitor the core systems, detect deviations early, and intervene before the problem compounds into a costly failure or a dangerous breakdown.

Oil pressure is the lifeline of the engine’s moving parts. It is the measure of how well the lubrication system is delivering a film of oil to bearings, shafts, cam lobes, and countless other surfaces that convert fuel into motion. A steady, adequate oil pressure is a sign that the oil pump, the oil gallery network, and the oil itself are performing as intended. In contrast, even a momentary dip can herald trouble that will not resolve on its own. Low oil pressure is a red flag: it may indicate insufficient oil supply due to leaks, worn pump components, or a sudden oil consumption spike. It can also reflect a deterioration in oil quality or viscosity, something that happens when oil becomes degraded by heat or contamination. The consequences of sustained low oil pressure are severe. Parts that rely on consistent lubrication begin to wear more quickly, clearances shrink as metals operate under increased friction, and, in the worst case, the engine can seize when metal-to-metal contact becomes catastrophic. For a driver in a live traffic situation, a rapid drop in oil pressure demands immediate attention: reduce engine speed if safe to do so, avoid heavy throttle, and plan a controlled stop to inspect oil level and potential leaks. The precise thresholds for alarm or driver action vary with engine design and operating conditions, but the underlying principle holds: any sustained deviation from normal oil pressure is a signal to pause, diagnose, and, if needed, repair.

Meanwhile, the coolant temperature gauge serves as the other half of the engine’s health check. It tracks the temperature of the coolant circulating through the block and head, a fluid that tames the heat of hundreds of thousands of pistons firing each minute. The coolant temperature tells a story about how efficiently the cooling system is removing excess heat. When readings sit in a healthy range, the cooling system is successfully protecting the engine from overheating, and the engine can sustain performance over long hours and across mountains of terrain. But when the coolant temperature climbs too high, the story shifts to danger: an overheating condition can accelerate component wear, degrade lubricants, and, in extreme cases, warp cylinders or head gaskets. Overcooling is another potential issue in some conditions, especially during cold starts or in engines that struggle to reach operating temperature. A coolant reading that remains low or fluctuates erratically can indicate thermostat problems, a failing water pump, a clogged radiator, or a leak in the cooling circuit. Either extreme—overheating or underheating—alters combustion efficiency, fuel economy, and emission performance, and it prompts corrective action before a trip becomes a costly incident.

What makes these two gauges so indispensable is not just the numbers they present, but the way their readings interact. In practical terms, a driver or maintenance technician reads the oil pressure alongside the coolant temperature to build a quick, accurate picture of the engine’s state. If oil pressure is normal but coolant temperature spikes, the issue is more likely in the cooling system—perhaps a failed thermostat or a water pump bottleneck—than in the lubrication system. Conversely, a sudden fall in oil pressure with a normal coolant temperature might point toward lubrication issues such as a deteriorated oil seal or a failed pump rather than a cooling system fault. When both gauges move in unexpected directions, the fault could be systemic, involving supply lines, sensors, or control logic that governs engine operation. In that sense, the two gauges act as a simple, robust diagnostic framework that supports rapid decision-making under real-world operating pressure. Such interpretive clarity is crucial on the road, where hesitation costs time and may escalate risk.

Industry practice reinforces the primacy of these gauges. Continuous monitoring is a cornerstone of preventive maintenance, a philosophy that keeps fleets productive and safe. Real-time data from oil pressure and coolant temperature not only guides immediate driving decisions but also informs longer-term maintenance planning. A driver who notes a trending drop in oil pressure or a creeping rise in coolant temperature can coordinate with maintenance teams to schedule servicing before the next heavy-load leg of a route. In a modern fleet, this approach translates into fewer unscheduled breakdowns, lower repair costs, and improved uptime, which in turn supports more predictable delivery schedules and better overall asset utilization. The value lies not in reacting to a single anomalous reading but in recognizing patterns and establishing a baseline that accounts for engine age, climate, load, and duty cycle. Fleet managers who cultivate this data-driven mindset tend to see fewer surprises on winter nights or hot desert days, where the margin for error is slim and the consequences of a fault can cascade across a network of operations.

Beyond the daily realities of driving and maintenance, the case for robust oil pressure and coolant temperature gauges rests on a broader understanding of engine design and operation. In diesel engines, lubrication and cooling are tightly coupled to performance and longevity. Lubrication reduces wear that would otherwise degrade parts with every revolution; cooling keeps combustion temperatures within safe limits to protect pistons, valves, and turbochargers from heat-induced damage. Operators who maintain vigilant watch over these two gauges recognize that engine health is not a static condition but a dynamic balance. Under heavy load, such as climbing grades with payloads or during rapid acceleration to merge into traffic, the engine temperature profile shifts and the oil’s viscosity can change as it warms. The interplay of oil pressure and coolant temperature thus becomes a practical gauge of how well the engine’s most critical systems respond to demand. When readings stay within expected ranges, confidence rises in the engine’s resilience under typical operating conditions. When readings stray, the operator has a clear, actionable path: throttle management, route reconsideration, or a call to service. This is the essence of preventive maintenance in its simplest form—the ability to respond before a fault becomes a failure.

The educational value of these gauges also extends to how fleets approach sensor and instrument integrity. A gauge is only as good as its sensor and its mounting, its wiring and its calibration. A reading that drifts because of a poor sensor connection or a degraded wiring harness can mislead even a careful driver. In practice, technicians emphasize sound installation and routine verification. They check for proper mounting to avoid heat-induced sensor drift, confirm electrical grounds are solid to prevent erroneous readings, and ensure the sending unit is sealed against oil or coolant ingress that could skew results. This attention to detail matters because a correctly reading gauge is a key ally in a vehicle’s preventive maintenance program, while a misreading can lull a crew into a false sense of security or trigger unnecessary maintenance actions. In other words, accuracy is not a luxury; it is a safety-critical element of the entire gauge ecosystem on a heavy-duty truck.

Within the broader instrumentation suite, oil pressure and coolant temperature gauges sit alongside other indicators that fleets use to gauge overall health. A boost pressure gauge, for instance, reveals how hard a turbocharger is working and how effectively air is being compressed into the engine. An exhaust gas temperature gauge provides insight into combustion efficiency and can flag issues related to fuel delivery or exhaust flow. A transmission temperature gauge helps protect the drivetrain by signaling overheating that could degrade shifting performance or shorten the life of transmission gears. A differential temperature gauge can reveal abnormal heat generation in the axle, which may indicate lubrication problems or bearing wear. These many gauges collectively create a map of engine and component health, yet the oil pressure and coolant temperature gauges remain foundational. They are simple, reliable, and directly tied to the engine’s core competencies: lubrication and cooling. In practical terms, they underpin decisions about how aggressively to drive, how long to stay in stop-and-go traffic, and when to divert to a service facility for inspection.

This narrative about gauges is not about nostalgia for mechanical simplicity. It reflects a modern reality in which diesel trucks rely on continuous data streams to optimize performance and safety. The dashboards of today aggregate information from multiple sensors and present it in a way that is accessible to drivers who must read and interpret quickly. Even as electronic control units manage many engine functions, the human-in-the-loop aspect remains vital. A gauge reading delivered in clear, timely terms empowers the operator to act decisively. It also reinforces a culture of accountability within maintenance teams. When a driver consistently reports readings at or near the edge of acceptable ranges, it becomes a signal to the shop to examine fuel filters, oil quality, or cooling system components. In this sense, the oil pressure and coolant temperature gauges are not merely diagnostic tools; they are surrogates for collective sensory input—an early warning system that translates miles, loads, and climates into concrete, actionable steps.

Engineers and fleet managers increasingly recognize the importance of establishing baselines tailored to each engine and duty cycle. A baseline accounts for factors such as ambient temperature, altitude, typical load, and the engine’s age. Deviations from the baseline are then interpreted with an understanding of the system’s physics. A slight uptick in coolant temperature during a steep grade, for example, may be expected and acceptable if the engine remains within a safe margin and the rise quickly reverses under steady throttle. A sustained high temperature, however, signals a cooling system problem that needs immediate attention. Likewise, oil pressure may vary with engine speed and temperature, but a significant drop from baseline at a given RPM is a cue to pull over, inspect, and troubleshoot. This approach makes gauge readings more meaningful than raw numbers alone and helps translate data into timely, cost-effective actions. In the end, these gauges represent the bridge between engineering design and practical operation—the means by which a driver translates complex internal engine dynamics into straightforward decisions that keep the vehicle moving.

For operators who want to deepen their understanding without becoming technicians, a few principles stand out. First, maintenance programs should prioritize clean, well-sealed sensor interfaces and consistent oil quality. Dirty oil and contaminated coolant can both alter readings and speed wear, so oil and coolant change intervals should reflect operating conditions, not just factory schedules. Second, fleets should cultivate a habit of documenting readings and trends rather than reacting to single data points. Trend analysis helps distinguish normal variation from genuine emerging problems. Third, drivers should be trained to respond to gauge signals with predefined actions. This not only reduces the risk of human error but also aligns on-road responses with long-term maintenance goals. Finally, the interface between gauges and maintenance records should be seamless, with readings logged in a way that supports predictive maintenance and helps optimize parts inventory and service planning. Taken together, these practices turn two simple instruments into a disciplined, effective approach to truck health and reliability.

Within this framework, it is useful to acknowledge a broader regulatory and market context. Industry standards and evolving emissions regulations influence how gauges are used and interpreted. Vehicle manufacturers and engine designers seek clarity in regulations to ensure that instrumentation supports compliance and efficient operation under varied duty cycles. This alignment between instrumentation and regulatory expectations helps fleets stay compliant while still maximizing uptime and performance. It is a reminder that gauges are not merely about immediate mechanical health; they are also about aligning operational realities with the standards that shape the industry’s future. For readers seeking a broader perspective on how manufacturers navigate these regulatory landscapes, see OEMs seek clarity in emissions regulations.

In sum, the oil pressure and coolant temperature gauges are the quiet guardians of the diesel truck’s life and livelihood. They distill the engine’s complex thermal and lubricating dynamics into clear signals that drivers can respond to with confidence. When used as part of a broader, data-informed maintenance program, these gauges help fleets avert failures, minimize downtime, and extend engine life. They are a practical reminder that the long-haul journey depends not only on power and fuel but also on the steady, disciplined observation of two fundamental metrics that keep the engine singing through miles of road and into the next horizon. External references and additional readings can provide deeper context, such as general gauge listings and their place in aftermarket instrumentation.

External reference for a general gauge listing: https://www.aliexpress.com/item/1005002963433760.html

Final thoughts

A comprehensive understanding of the gauges in commercial diesel trucks—from oil pressure and coolant temperature to exhaust gas temperature—is vital for ensuring safe and efficient operation. Each gauge plays a crucial role in engine monitoring and preventative maintenance, helping to avert costly repairs and ensuring compliance with operational standards. By prioritizing the maintenance of these gauges, logistics and freight companies, construction operations, and small delivery fleets can safeguard their investments and enhance their operational capabilities.